Page 17 - Industrial Plants 2014

P. 17

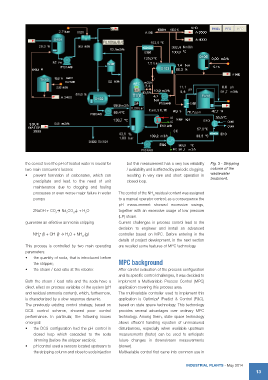

the correct level the pH of treated water is crucial for but this measurement has a very low reliability Fig. 3 - Stripping

two main concurrent factors: / availability and is affected by periodic clogging, column of the

• prevent formation of carbonates, which can resulting in very rare and short operation in wastewater

precipitate and lead to the need of unit closed loop. treatment.

maintenance due to clogging and fouling

processes or even worse major failure in water The control of the NH residual content was assigned

3

pumps to a manual operator control; as a consequence the

pH measurement showed excessive swings,

2NaOH + CO ? Na CO ? + H O together with an excessive usage of low pressure

2 2 3 2

(LP) steam.

guarantee an effective ammonia stripping Current challenges in process control lead to the

decision to engineer and install an advanced

+

NH (l) + OH (l) ? H O + NH (g) controller based on MPC. Before entering in the

-

2

3

4

details of project development, in the next section

This process is controlled by two main operating are recalled some features of MPC technology.

parameters:

• the quantity of soda, that is introduced before

the stripper; MPC background

• the steam / load ratio at the reboiler. After careful evaluation of the process configuration

and its specific control challenges, it was decided to

Both the steam / load ratio and the soda have a implement a Multivariable Process Control (MPC)

direct effect on process variables of the system (pH application covering this process area.

and residual ammonia content), which, furthermore, The multivariable controller used to implement this

is characterized by a slow response dynamic. application is Optimize Predict & Control (P&C),

IT

The previously existing control strategy, based on based on state space technology. This technology

DCS control scheme, showed poor control provides several advantages over ordinary MPC

performance. In particular, the following issues technology. Among them, state space technology

emerged: allows efficient handling rejection of unmeasured

• the DCS configuration had the pH control in disturbances, especially when available upstream

closed loop which cascaded to the soda measurements (faster) can be used to anticipate

trimming (before the stripper section); future changes in downstream measurements

• pH control used a sensors located upstream to (slower).

the stripping column and close to soda injection Multivariable control first came into common use in

IndustrIal Plants - May 2014

13