Page 65 - Industrial Plants 2014

P. 65

Enhancing Energy Efficiency

of Gas Turbines

Mann+Hummel Vokes Air demonstrates the straightforward actions

of retrofit to existing air intakes

Thomas Helf, Carlo Coltri

Mann+Hummel Vokes Air

urope’s larger combined-cycle power prefilter and final filter, the second turbine trialled a new

plants are currently navigating rough filter which condensed the first two stages into one.

seas. Low-cost US coal, renewable Macrogen GT Duo employs a hydrophobic media that

energy and economic crisis have all provides effective water removal whilst also delivering

combined to slash the average running particle filtration to G4 or M5 efficiencies. This means

E hours of plants that utilize gas turbine that separate coalescer and prefiltration stages are

technology. In this market, energy operators are unnecessary and that the redundant filter phase can be

focused more on flexibility than the efficiency of their removed (figure 1).

equipment. This situation with two air intakes in near identical

Nevertheless, there remain a number of smaller gas environments provided an excellent opportunity to

turbine facilities that are continuing to work baseload. demonstrate the benefits of employing a combined

CHP (Combined Heat and Power) and district heating coalescer/prefilter system.

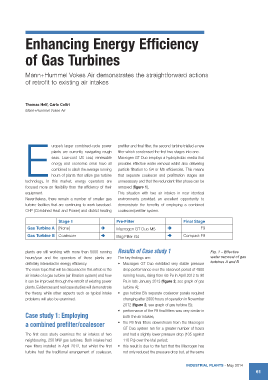

Stage 1 Pre-Filter Final Stage

Gas Turbine A [None] ? Macrogen GT Duo M5 ? Compact F9

Gas Turbine B Coalescer ? Bag Filter G4 ? Compact F9

plants are still working with more than 5000 running Results of Case study 1 Fig. 1 – Effective

hours/year and the operators of these plants are The key findings are: water removal of gas

definitely interested in energy efficiency. • Macrogen GT Duo exhibited very stable pressure turbines A and B

The main topic that will be discussed in this article is the drop performance over the observed period of 4800

air intake of a gas turbine (air filtration system) and how running hours, rising from 65 Pa in April 2012 to 90

it can be improved through the retrofit of existing power Pa in late January 2013 (figure 2, see graph of gas

plants. Evidences and real case studies will demonstrate turbine A);

the theory, while other aspects such as typical intake • gas turbine B’s separate coalescer panels required

problems will also be examined. changing after 2000 hours of operation in November

2012 (figure 2, see graph of gas turbine B);

• performance of the F9 final filters was very similar in

Case study 1: Employing both the air intakes;

a combined preflter/coalescer • the F9 final filters downstream from the Macrogen

GT Duo system ran for a greater number of hours

The first case study examines the air intakes of two and had a slightly lower pressure drop (105 against

neighbouring, 250 MW gas turbines. Both intakes had 110 Pa) over the trial period;

new filters installed in April 2012, but whilst the first • this result is due to the fact that the Macrogen has

turbine had the traditional arrangement of coalescer, not only reduced the pressure drop but, at the same

IndustrIal Plants - May 2014

61