Page 57 - Impiantistica industriale Luglio Agosto 20147

P. 57

Safety prevails over everything are also diffcult to source in the local market.

In other words: no compromise on safety princi- On the other hand, hiring specialized manpower

ples is allowed. Safety is an essential core value and deploying it in the area would have been

for Foster Wheeler (and important for the other expensive and hard to realize. Modularization

member of the consortium) and must be follo- was the chosen solution to address this chal-

wed frst. The question which we have always lenge and also to facilitate safer working. The

to answer when we plan something is: “Can we new refnery has been designed in modules

do it in a different way to improve safety?” If the which will be built in the Far East, offoaded in

response is yes, we have to implement it. Despi- selected oceanic ports and fnally transshipped

te any impact on cost and schedule objectives to the site.

which can occur.

Use the best skills where

Uniformity doesn’t mean available

uniqueness One of the characteristic of the DT is its lean

The project needed common bases. That is, structure. No specialist belongs to the DT and

engineering standards, basic specifcations, the DT is able to defne the content of the main

process philosophies, management procedures strategies but not to develop the documentation

that are valid for all the members of the consor- to properly address them. For this reason the DT

tium and applicable by everyone. However this assigned to each ET the precise task to develop

did not imply in itself that the normal practices the general standards and procedures accor-

and design tools of each EC had been “turned ding to their specifc areas of excellence. Foster

upside-down”. The common standards fx the Wheeler, who is recognized as world leader in

criteria (i.e. the “what?”) but do not determine modular design, has been selected to prepare

the method of satisfying them (i.e. the “how?”). the job specifcation for modularization.

For example they establish the required bearing

capacity for the foundations or the pressure

conditions at the battery limits but how to cal- The project is a cost-driven

culate a foundation or the pressure drop along project

a transfer line is part of the expertise and the

know-how of each company and remains within The consortium carried out many studies to

this boundary. analyze the main criticalities of the project. At

the end the cost has been identifed as the most

Build safely outside the plot critical parameter, classifying the job as a cost-

driven project. This is mainly due to the necessi-

The in-country work force is neither suffcient nor ty to keep under a specifc ceiling the investment

specialized enough to build a so complex facility. and limit the associated cost. In this perspective

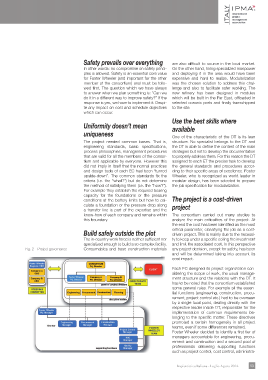

Fig. 2 – Project governance Consumables and base construction materials any project decision, except for safety, has been

and will be determined taking into account its

cost impact.

Each EC designed its project organization con-

sidering the scope of work, the usual manage-

ment structure and the relations with the DT. It

has to be noted that the consortium established

some general rules. For example all the essen-

tial functions (engineering, construction, procu-

rement, project control etc.) had to be overseen

by a single focal point, dealing directly with the

respective leader inside DT, responsible for the

implementation of common requirements be-

longing to the specifc matter. These directives

promoted a certain homogeneity in all project

teams, even if some differences remained.

Foster Wheeler decided to identify a frst tier of

managers accountable for engineering, procu-

rement and construction and a second pool of

professionals delivering supporting functions

such as project control, cost control, administra-

Impiantistica Italiana - Luglio-Agosto 2014 53 53