Page 49 - Industrial Plants

P. 49

Saipem engaged in the Field

Development Project for the

“supergiant” Zohr gas field,

located off the Egyptian coast

in the Mediterranean sea

Located 200 km offshore at a water depth of approximately

1,700 m, the Egyptian Zhor supergiant field is the largest gas find

ever made in the Mediterranean Sea. Since its discovery in 2015

by Eni, it has undergone an ambitious 3 phase development plan

conceived and implemented for its exploitation

Giulio Fatica, responsible of the Subsea Engineering of Saipem SA

Piergiovanni Panico, Project Manager for Engineering and Procurement activities of Zohr Development Project

n April 2016 Saipem was awarded the contract

for the Engineering, Procurement, Construction

and Installation (EPCI) of the first and most

challenging phase (Accelerated Start-Up) aimed

at ensuring early production by the end of 2017

Iwith the tie-in of the first 2 wells by September REM

2017.

To achieve such a challenging target, and to support

the in-Country execution operations, Saipem is TRM

ZOHR

leveraging its outstanding experience in similar fast-

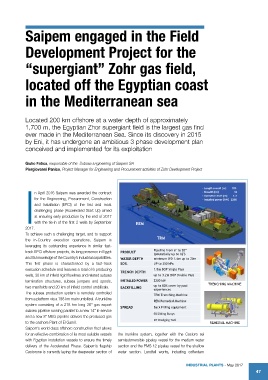

track EPCI offshore projects, its long presence in Egypt PRODUCT Pipeline from 6" to 28“

(potentially up to 32")

and its knowledge of the Country’s industrial capabilities. WATER DEPTH minimum WD 1.4m up to 20m

SHALLOW WATER

This first phase is characterised by a fast-track SOIL UP to 350 kPa

TRENCHING BARGE

execution schedule and features a total of 6 producing 1.8m BOP Single Pass

wells, 30 km of infield rigid flowlines and related subsea TRENCH DEPTH up to 3.2m BOP Double Pass

termination structures, subsea jumpers and spools, INSTALLED POWER 2200 kW

two manifolds and 20 km of infield control umbilicals. BACKFILLING up to 80% cover by past TRENCHING MACHINE

The subsea production system is remotely controlled experiences

TRM Trenching Machine

from a platform via a 158 km main umbilical. A trunkline REM Remedial Machine

system consisting of a 218 km long 26” gas export

subsea pipeline running parallel to a new 14” in-service SPREAD Back Filling equipment

and a new 8” MEG pipeline delivers the produced gas SB Sliding Buoys

to the onshore Plant of El Gamil. DT Dredging Tool REMEDIAL MACHINE

giovedì 16 febbraio 2017

Saipem’s world class offshore construction fleet allows

for an effective combination of its most suitable vessels the trunkline system, together with the Castoro sei

with Egyptian installation vessels to ensure the timely semisubmersible pipelay vessel for the medium water

delivery of the Accelerated Phase. Saipem’s flagship section and the PMS 12 pipelay vessel for the shallow

Castorone is currently laying the deepwater section of water section. Landfall works, including cofferdam

IndustrIal Plants - May 2017

47