Page 50 - Industrial Plants

P. 50

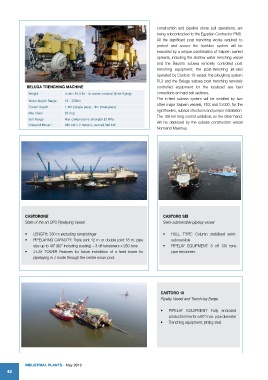

BELUGA MAIN CHARACTERISTICS

construction and pipeline shore pull operations, are

being subcontracted to the Egyptian Contractor PMS.

All the significant post trenching works required to

protect and secure the trunkline system will be

executed by a unique combination of Saipem owned

spreads, including the shallow water trenching vessel

and the Bautino subsea remotely controlled post

trenching equipment; the post-trenching jet-sled

ZOHR operated by Castoro 10 vessel; the ploughing system

PL3 and the Beluga subsea post trenching remotely

BEluGA TRENChING MAChINE controlled equipment for the localized sea bed

BELUGA Weight In air: 14.5 Te – In water: neutral (free flying) corrections on hard soil sections.

MSV3 Water Depth Range 15 - 2250m The in-field subsea system will be installed by two

other major Saipem vessels, FDS and S7000, for the

Trench Depth 1.4m (single pass) – 4m (multipass)

rigid flowline, subsea structures and jumper installation.

Max Slope 20 deg

The 158 km long control umbilical, on the other hand,

Soil Range Max compressive strength 30 MPa

will be deployed by the subsea construction vessel

Onboard Power: 280 kW x 2 motors, overall 560 kW

Normand Maximus.

giovedì 16 febbraio 2017

giovedì 16 febbraio 2017

CASTORONE CASTORO SEI

State of the art DP3 Pipelaying Vessel Semi-submersible pipelay vessel

• LENGTH: 330 m excluding ramp/stinger • HULL TYPE: Column stabilised semi-

• PIPELAYING CAPACITY: Triple joint 12 m or double joint 18 m; pipe submersible

size up to 48” (60” including coating) – 3 off tensioners x 250 tons • PIPELAY EQUIPMENT: 3 off 130 tons

• J-LAY TOWER Features for future installation of a fixed tower for pipe tensioners

pipelaying in J mode through the centre moon pool.

CASTORO 10

Pipelay Vessel and Trench-lay Barge

• PIPELAY EQUIPMENT Fully enclosed

production line for a 60” max. pipe diameter

• Trenching equipment; jetting sled

IndustrIal Plants - May 2016

48