Page 83 - Industrial Plants

P. 83

“Minerbio Storage Field” and “Tavazzano

Thermoelectric Plant”.

Even in this case, hydrogen valves are tested in our

laboratory, which has been recently expanded to fit a

Hydro/Gas test bench that can test valves up to

15,000 PSI.

Indra is committed to consolidating its position in

these markets and developing solutions and strategies

to be qualified by end-users.

Certifications

To meet the requirements of clients and the market,

Indra has obtained a considerable number of technical

certifications, including API 598 / API 6D / API 602 /

PED 97/23/CE.

Moreover, as an ISO 9001, 14001 and 45001-certified

company, Indra is committed to protecting the

environment by reducing its environmental impact,

energy consumption, and waste production.

Therefore, certifications are essential to ensure

product conformity to the standards in force in EU and

non-EU countries.

The international role

Indra has an international outlook. That’s why, over the

years, the company has built a sales network in

strategic areas through selected distributors.

Participating in important events in the oil and gas

sector highlights Indra’s determination to establish

itself as a major player in the Italian and international

markets.

Indra products

Ball valves

In the oil industry, safety plays a crucial role, a

prerequisite for developing the ball valve range. In the

“DBB” version, they replace the traditional “Christmas

Tree”, combining several functions in one valve body.

Besides improving the system’s efficiency, these

valves reduce costs and installation and maintenance

times.

All valves can come with various accessories, such as

lock systems and electric signals, improving safety

and efficiency.

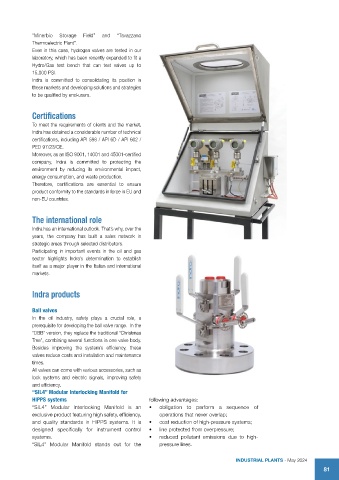

“SIL4” Modular Interlocking Manifold for

HIPPS systems following advantages:

“SIL4” Modular Interlocking Manifold is an • obligation to perform a sequence of

exclusive product featuring high safety, efficiency, operations that never overlap;

and quality standards in HIPPS systems. It is • cost reduction of high-pressure systems;

designed specifically for instrument control • line protected from overpressure;

systems. • reduced pollutant emissions due to high-

“SIL4” Modular Manifold stands out for the pressure lines.

IndustrIal Plants - May 2024

81