Page 34 - Impiantistica Italiana Maggio Giugno 2014

P. 34

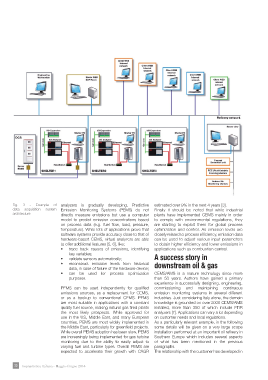

Fig. 3 - Example of analyzers is gradually developing. Predictive estimated over 9% in the next 4 years [3].

data acquisition system Emission Monitoring Systems (PEMS) do not Finally it should be noted that while industrial

architecture directly measure emissions but use a computer plants have implemented CEMS mainly in order

model to predict emission concentrations based to comply with environmental regulations, they

on process data (e.g. fuel fow, load, pressure, are starting to exploit them for global process

temperature). While lots of applications prove that optimization and control. As emission levels are

software systems provide accuracy close to that of closely related to process effciency, emission data

hardware-based CEMS, virtual analyzers are able can be used to adjust various input parameters

to offer additional features [5, 6], like: to obtain higher effciency and lower emissions in

• trace back causes of emissions, identifying applications such as combustion control.

key variables;

• validate sensors automatically; A success story in

• reconstruct emission levels from historical downstream oil & gas

data, in case of failure of the hardware device;

• can be used for process optimization CEMS/AMS is a mature technology since more

purposes. than 50 years. Authors have gained a primary

experience in successfully designing, engineering,

PEMS can be used independently for qualifed commissioning and maintaining continuous

emissions sources, as a replacement for CEMS, emission monitoring systems in several different

or as a backup to conventional CEMS. PEMS industries. Just considering Italy alone, the domain

are most suitable in applications with a constant knowledge is grounded on over 2000 CEMS/AMS

quality fuel source, making natural gas fred plants installed, more than 350 of which include FTIR

the most likely prospects. While approved for analyzers [7]. Applications can vary a lot depending

use in the US, Middle East, and many European on customer needs and local regulations.

countries, PEMS are most widely implemented in As a particularly relevant example, in the following

the Middle East, particularly for greenfeld projects. some details will be given on a very large scope

While overall PEMS adoption has been slow, PEMS installation performed at an important oil refnery in

are increasingly being implemented for gas turbine Southern Europe which includes several aspects

monitoring due to the ability to easily adjust to of what has been mentioned in the previous

varying fuel and turbine types. Overall PEMS are paragraphs.

expected to accelerate their growth with CAGR The relationship with the customer has developed in

30 Impiantistica Italiana - Maggio-Giugno 2014