Page 33 - Impiantistica Italiana Maggio Giugno 2014

P. 33

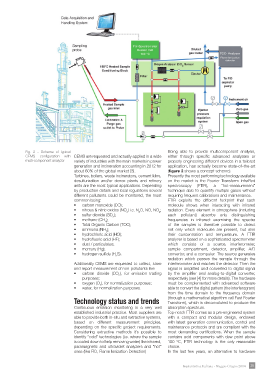

Fig. 2 - Scheme of typical Being able to provide multicomponent analysis,

CEMS confguration with CEMS are requested and actually applied in a wide either through specifc advanced analyzers or

multi-component analyzer variety of industries with the main markets in power properly engineering different devices in a tailored

generation and incineration accounting in 2012 for application, has actually become state-of–the-art

about 60% of the global market [3]. (fgure 2 shows a concept scheme).

Turbines, boilers, waste incinerators, cement kilns, Presently the most performing technology available

desulfurization and/or denox plants and refnery on the market is the Fourier Transform InfraRed

units are the most typical applications. Depending spectroscopy (FTIR), a “hot-measurement”

by production details and local regulations several technique able to quantify multiple gases without

different pollutants could be monitored, the most requiring frequent calibrations and maintenance.

common being: FTIR exploits the different footprint that each

• carbon monoxide (CO); molecule shows when interacting with infrared

• nitrous & nitric oxides (NO ) i.e. N O, NO, NO ; radiation. Every element in atmosphere (including

2

x

2

• sulfur dioxide (SO ); each pollutant) absorbs only distinguishing

2

• methane (CH ); frequencies in infrared: examining the spectra

4

• Total Organic Carbon (TOC); of the samples is therefore possible to detect

• ammonia (NH ); not only which molecules are present, but also

3

• hydrochloric acid (HCl); their concentration and temperature. A FTIR

• hydrofuoric acid (HF); analyzer is based on a sophisticated spectrometer

• dust / particulates; which consists of a source, interferometer,

• mercury (Hg); sample compartment, detector, amplifer, A/D

• hydrogen sulfde (H S). convertor, and a computer. The source generates

2

radiation which passes the sample through the

Additionally CEMS are requested to collect, store interferometer and reaches the detector. Then the

and report measurement of non-pollutants like: signal is amplifed and converted to digital signal

• carbon dioxide (CO ), for emission trading by the amplifer and analog-to-digital converter,

2

purposes; respectively (see [4] for more details). The hardware

• oxygen (O ), for normalization purposes; must be complemented with advanced software

2

• water, for normalization purposes. able to convert the digital pattern (the interferogram)

from the time domain to the frequency domain

Technology status and trends (through a mathematical algorithm call Fast Fourier

Transform), which is deconvoluted to produce the

Continuous emission monitoring is a very well absorption spectrum.

established industrial practice. Most suppliers are Top-notch FTIR comes as a pre-engineered system

able to provide both in-situ and extractive systems, with a compact and modular design, endowed

based on different measurement principles, with latest generation communication, control and

depending on the specifc project requirements. maintenance protocols and are compliant with the

Considering extractive methods it’s possible to most demanding certifcations. When the sample

identify “cold” technologies (i.e. where the sample contains acid components with dew point above

is cooled down to help removing water) like infrared, 100 ºC, FTIR technology is the only reasonable

paramagnetic and ultraviolet analyzers and “hot” choice.

ones (like FID, Flame Ionization Detection) In the last few years, an alternative to hardware

Impiantistica Italiana - Maggio-Giugno 2014 29