Page 26 - Industrial Plants

P. 26

satisfy the need of improving the efficiency and of

getting a faster power response.

Hybrid propulsion assisted by

energy storage system

The basic schematic of the electric system of an hybrid

tug is shown in fig.2. The solution provides two shaft

lines, driving the thrusters. Each shaft is driven by an

ICE and a PEM is mounted on the same shaft or on the

gearbox. The PEM can drive the propeller by itself or in

parallel to the main diesel. For each shaft line an

electric Power Unit is provided. The Power Unit

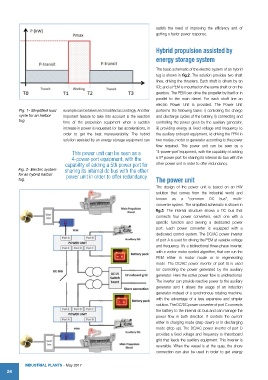

Fig. 1- Simplified load example can be taken and modified accordingly. Another performs the following tasks: i) controlling the charge

cycle for an harbor important feature to take into account is the reaction and discharge cycles of the battery, ii) connecting and

tug. time of the propulsion equipment when a sudden controlling the power given by the auxiliary generator,

increase in power is requested for fast accelerations, in iii) providing energy at fixed voltage and frequency to

order to get the best maneuverability. The hybrid the auxiliary onboard equipment, iv) driving the PEM in

solution assisted by an energy storage equipment can two modes, motor or generator according to the power

flow required. This power unit can be seen as a

This power unit can be seen as a “4-power-port”equipment, with the capability of adding

th

4-power-port equipment, with the a 5 power port for sharing its internal dc bus with the

capability of adding a 5th power port for other power unit in order to offer redundancy.

Fig. 2- Electric system sharing its internal dc bus with the other

for an hybrid harbor power unit in order to offer redundancy

tug. The power unit

The design of the power unit is based on an HW

solution that comes from the industrial world and

known as a “common DC bus”, multi-

converter system. The simplified schematic is shown in

fig.3. The internal structure shows a DC bus that

connects four power converters, each one with a

specific function and serving a dedicated power

port. Each power converter is equipped with a

dedicated control system. The DC/AC power inverter

of port A is used for driving the PEM at variable voltage

and frequency. It’s a bidirectional three-phase inverter,

with a vector motor control algorithm, that can run the

PEM either in motor mode or in regenerating

mode. The DC/AC power inverter of port B is used

for controlling the power generated by the auxiliary

generator. Here the active power flow is unidirectional.

The inverter can provide reactive power to the auxiliary

generator and it allows the usage of an induction

generator instead of a synchronous rotating machine,

with the advantage of a less expensive and simpler

solution. The DC/DC power converter of port C connects

the battery to the internal dc bus and can manage the

power flow in both direction. It controls the current

either in charging mode (step down) or in discharging

mode (step up). The DC/AC power inverter of port D

provides a fixed voltage and frequency to theonboard

grid that feeds the auxiliary equipment. This inverter is

reversible. When the vessel is at the quay, the shore

connection can also be used in order to get energy

IndustrIal Plants - May 2017

24