Page 85 - Industrial Plants

P. 85

and its pressure required the use of super duplex

stainless steel for the pressure components.

In fact, Termomeccanica had to reconcile the

mechanical features of the pressure components, that

pushed towards increasing thicknesses, with the

metallurgic difficulties of super duplex production that

grow in parallel to the increase of the material

thicknesses.

The choice of super duplex A890 gr.5A

for wet components was made in

agreement with the EPC engineering

team, considering the characteristics of

the pumped fluid, i.e. seawater, so as to

guarantee the best protection against

corrosion

The first technical challenge was the development of a

barrel casing with proper dimensions, without

unnecessary layers of material and, most important of

all, with regular and constant thickness along its entire

length.

Once the design of the barrel casing was finalized, the

second challenge consisted in adjusting it to make its

casting feasible, i.e. respecting the restrictions related

to the pouring of this type of material, finding the proper

and most suitable process and the right size and

position of risers and sprues to guarantee a successful

outcome. For Super Duplex material, this part of the

design is fundamental to prevent unwanted severe

T he four pumps are API 610 BB5 type achieve the proper final result in terms of mechanical

defects due to the formation of fragile phases and to

multistage pumps made of super

properties.

duplex stainless steel, characterised

The use of the most advanced computational tools and

by 300 m³/h flow and 2,160 m head,

a close collaboration with not only foundries and

and driven by a 3 MW motor rotating

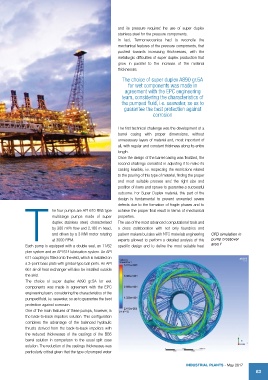

pump crossover

at 3000 RPM.

experts allowed to perform a detailed analysis of this

area 1

specific design and to define the most suitable heat

Each pump is equipped with a double seal, an 11/62 pattern makers but also with NTC materials engineering CFD simulation in

plan system and an API 614 lubrication system. An API

671 coupling is fitted onto the skid, which is installed on

a 3-point base plate with gimbal-type ball joints. An API

661 air-oil heat exchanger will also be installed outside

the skid.

The choice of super duplex A890 gr.5A for wet

components was made in agreement with the EPC

engineering team, considering the characteristics of the

pumped fluid, i.e. seawater, so as to guarantee the best

protection against corrosion.

One of the main features of these pumps, however, is

the back-to-back impellers solution. This configuration

combines the advantage of the balanced hydraulic

thrusts derived from the back-to-back impellers with

the reduced thicknesses of the castings of the BB5

barrel solution in comparison to the usual split case

solution. The reduction of the castings thicknesses was

particularly critical given that the type of pumped water

IndustrIal Plants - May 2017

83