Page 81 - Industrial Plants

P. 81

Pict. 20 - load out gates Pict. 21 - rotation

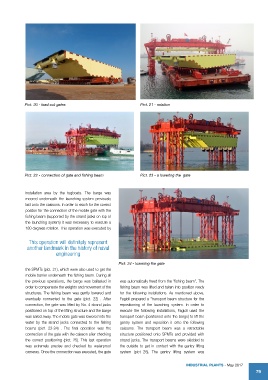

Pict. 22 - connection of gate and fishing beam Pict. 23 - a lowering the gate

installation area by the tugboats. The barge was

moored underneath the launching system previously

laid onto the caissons. In order to reach for the correct

positon for the connection of the mobile gate with the

fishing beam (supported by the strand jacks on top of

the launching system) it was necessary to execute a

180 degrees rotation. This operation was executed by

This operation will definitely represent

another landmark in the history of naval

engineering

Pict. 24 - lowering the gate

the SPMTs (pict. 21), which were also used to get the

mobile barrier underneath the fishing beam. During all

the previous operations, the barge was ballasted in was automatically freed from the “fishing beam”. The

order to compensate the weights and movement of the fishing beam was lifted and taken into position ready

structures. The fishing beam was gently lowered and for the following installations. As mentioned above,

eventually connected to the gate (pict. 22) . After Fagioli prepared a “transport beam structure for the

connection, the gate was lifted by No. 4 strand jacks repositioning of the launching system. In order to

positioned on top of the lifting structure and the barge execute the following installations, Fagioli used the

was sailed away. The mobile gate was lowered into the transport beam (positioned onto the barge) to lift the

water by the strand jacks connected to the fishing gantry system and reposition it onto the following

beams (pict. 23-24) . The final operation was the caissons. The transport beam was a retractable

connection of the gate with the caisson after checking structure positioned onto SPMTs and provided with

the correct positioning (pict. 25). This last operation strand jacks. The transport beams were skidded to

was extremely precise and checked by waterproof the outside to get in contact with the gantry lifting

cameras. Once the connection was executed, the gate system (pict 26). The gantry lifting system was

IndustrIal Plants - May 2017

79