Page 47 - Industrial Plant 2015

P. 47

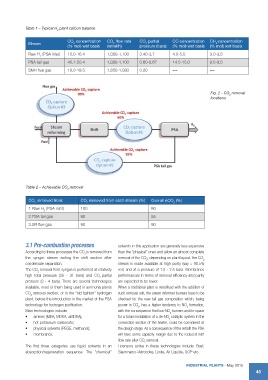

Table 1 – Typical H2 plant carbon balance

Stream C(%O2mcool)nwceenttbraatsioisn (CkOm2ofll/ohw) rate CprOes2 spuarretia(bl ara) CO concentration (C%H4mcooln) cweenttrbaatisoisn

15.0-16.4 1,000-1,100 3.40-3.7 (% mol) wet basis 3.0-3.5

Raw H2 (PSA inlet) 45.1-50.4 1,000-1,100 0.60-0.67 8.5-9.5

PSA tail gas 19.0-19.5 1,850-1,930 0.20 4.0-5.0 ==

SMR flue gas

14.5-15.0

==

Fig. 2 - CO2 removal

locations

Table 2 – Achievable CO2 removal

CO2 removed from: CO2 removed from each stream (%) Overall ηCO2 (%)

1.Raw H2 (PSA inlet) 100 60

2.PSA tail gas 90 55

90 90

3.SR flue gas

3.1 Pre-combustion processes solvents in this application are generally less expensive

According to these processes the CO2 is removed from than the “physical” ones and allow an almost complete

the syngas stream exiting the shift section after

condensate separation. removal of the CO2; depending on plant layout, the CO2

The CO2 removal from syngas is performed at relatively stream is made available at high purity (say > 98.5%

high total pressure (26 - 31 bara) and CO2 partial

pressure (3 - 4 bara). There are several technologies vol.) and at a pressure of 1.5 - 2.5 bara. Membranes

available, most of them being used in ammonia plants

CO2 removal section, or in the “old fashion” hydrogen performances in terms of removal efficiency and purity

plant, before the introduction in the market of the PSA

technology for hydrogen purification. are expected to be lower.

Main technologies include:

• amines (MEA, MDEA, aMDEA); When a traditional plant is retrofitted with the addition of

• hot potassium carbonate;

• physical solvents (PEGE, methanol); such removal unit, the steam reformer burners have to be

• membranes.

checked for the new tail gas composition which, being

The first three categories use liquid solvents in an

absorption/regeneration sequence. The “chemical” poorer in CO2, has a higher tendency to NOx formation,

with the consequence that low-NOx burners and/or space

for a future installation of a de-NOx catalytic system in the

convection section of the heater, could be considered at

the design stage. As a consequence of the retrofit the PSA

will have some capacity margin due to the reduced inlet

flow rate after CO2 removal.

Licensors active in these technologies include: Basf,

Giammarco-Vetrocoke, Linde, Air Liquide, UOP etc.

Industrial Plants - May 2015

45