Page 52 - Industrial Plant 2015

P. 52

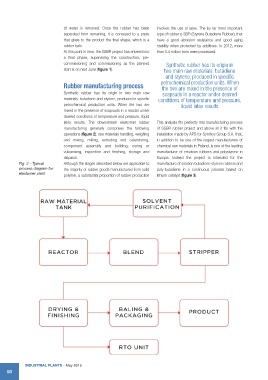

Fig. 2 - Typical of water is removed. Once the rubber has been involves the use of latex. The by far most important

process diagram for separated form remaining, it is conveyed to a press type of rubber is SBR (Styrene Butadiene Rubber), that

elastomer plant that gives to the product the final shape, which is a have a good abrasion resistance and good aging

rubber bale. stability when protected by additives. In 2012, more

At this point in time, the SSBR project has entered into than 5.4 million tons were processed.

a final phase, supervising the construction, pre-

commissioning and commissioning as the planned Synthetic rubber has its origin in

start is on next June (figure 1). two main raw materials: butadiene

and styrene, produced in specific

Rubber manufacturing process petrochemical production units. When

the two are mixed in the presence of

Synthetic rubber has its origin in two main raw soapsuds in a reactor under desired

materials: butadiene and styrene, produced in specific conditions of temperature and pressure,

petrochemical production units. When the two are

mixed in the presence of soapsuds in a reactor under liquid latex results

desired conditions of temperature and pressure, liquid

latex results. The downstream elastomer rubber This analysis fits perfectly into manufacturing process

manufacturing generally comprises the following of SSBR rubber project and above all it fits with the

operations (figure 2): raw materials handling, weighing installation made by APS for Synthos Group S.A. that,

and mixing, milling, extruding and calendaring, in addition to be one of the largest manufacturers of

component assembly and building, curing or chemical raw materials in Poland, is one of the leading

vulcanizing, inspection and finishing, storage and manufacturer of emulsion rubbers and polystyrene in

dispatch. Europe. Indeed the project is intended for the

Although the stages described below are applicable to manufacture of solution butadiene-styrene rubbers and

the majority of rubber goods manufactured from solid poly-butadiene in a continuous process based on

polymer, a substantial proportion of rubber production lithium catalyst (figure 3).

Industrial Plants - May 2015

50