Page 91 - Impiantitica industriale

P. 91

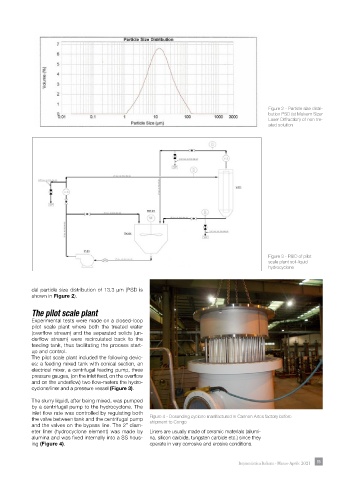

Figure 2 - Particle size distri-

bution PSD (at Malvern Sizer

Laser Diffraction) of non tre-

ated solution

Figure 3 - P&ID of pilot

scale plant soli-liquid

hydrocyclone

dal particle size distribution of 13.3 µm (PSD is

shown in Figure 2).

The pilot scale plant

Experimental tests were made on a closed-loop

pilot scale plant where both the treated water

(overflow stream) and the separated solids (un-

derflow stream) were recirculated back to the

feeding tank, thus facilitating the process start-

up and control.

The pilot scale plant included the following devic-

es: a feeding mixed tank with conical section, an

electrical mixer, a centrifugal feeding pump, three

pressure gauges, (on the inlet feed, on the overflow

and on the underflow) two flow-meters the hydro-

cyclone/liner and a pressure vessel (Figure 3).

The slurry liquid, after being mixed, was pumped

by a centrifugal pump to the hydrocyclone. The

inlet flow rate was controlled by regulating both

the valve between tank and the centrifugal pump Figure 4 - Desanding cyclone manifactured in Cannon Artes factory before

and the valves on the bypass line. The 2” diam- shipment to Congo

eter liner (hydrocyclone element) was made by Liners are usually made of ceramic materials (allumi-

alumina and was fixed internally into a SS hous- na, silicon carbide, tungsten carbide etc.) since they

ing (Figure 4). operate in very corrosive and erosive conditions.

Impiantistica Italiana - Marzo-Aprile 2021 85