Page 50 - Impiantistica industriale

P. 50

NEW TECHNOLOGIES

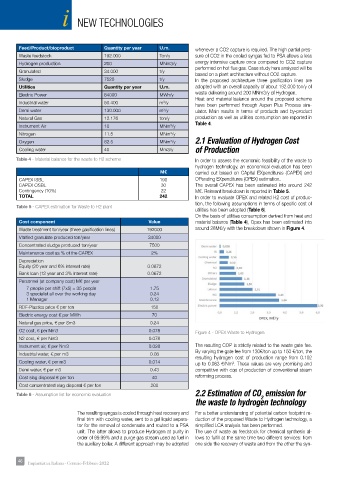

Feed/Product/bioproduct Quantity per year U.m. whenever a CO2 capture is required. The high partial pres-

Waste feedstock 192.000 Ton/y sure of CO2 in the cooled syngas fed to PSA allows a less

Hydrogen production 200 MNm3/y energy intensive capture once compared to CO2 capture

performed on hot flue gas. Case study here analyzed will be

Granulated 34.000 t/y

based on a plant architecture without CO2 capture.

Sludge 7520 t/y In the proposed architecture three gasification lines are

Utilities Quantity per year U.m. adopted with an overall capacity of about 192.000 ton/y of

Electric Power 84000 MWh/y waste delivering around 200 MNm3/y of Hydrogen.

Heat and material balance around the proposed scheme

Industrial water 50.400 m /y have been performed through Aspen Plus Process sim-

3

Demi water 130.000 m /y ulator. Main results in terms of products and by-product

3

Natural Gas 12.176 ton/y production as well as utilities consumption are reported in

Table 4.

Instrument Air 10 MNm /y

3

Nitrogen 11.5 MNm /y

3

Oxygen 82.5 MNm /y 2.1 Evaluation of Hydrogen Cost

3

Cooling water 40 Mm3/y of Production

Table 4 - Material balance for the waste to H2 scheme In order to assess the economic feasibility of the waste to

hydrogen technology, an economical evaluation has been

M€ carried out based on CApital EXpenditures (CAPEX) and

CAPEX ISBL 190 OPerating EXpenditures (OPEX) estimation.

CAPEX OSBL 30 The overall CAPEX has been estimated into around 242

Contingency (10%) 22 M€. Relevant breakdown is reported in Table 5.

TOTAL 242 In order to evaluate OPEX and related H2 cost of produc-

tion, the following assumptions in terms of specific cost of

Table 5 - CAPEX estimation for Waste to H2 plant

utilities has been adopted (Table 6).

On the basis of utilities consumption derived from heat and

Cost component Value material balance (Table 4), Opex has been estimated into

Waste treatment ton/year (three gasification lines) 192000 around 28M€/y with the breakdown shown in Figure 4.

Vitrified granulate produced ton/year 34000

Concentrated sludge produced ton/year 7500

Maintenance cost as % of the CAPEX 2%

Depreciation

Equity (20 year and 6% interest rate) 0.0872

Bank loan (12 year and 3% interest rate) 0.0672

Personnel (at company cost) M€ per year

7 people per shift (7x5) = 35 people 1.75

3 specialist all over the working day 0.24

1 Manager 0.12

RDF-Plastics price € per ton 150

Electric energy cost € per MWh 70

Natural gas price, € per Sm3 0.24

O2 cost, € per Nm3 0.078 Figure 4 - OPEX Waste to Hydrogen

N2 cost, € per Nm3 0.078

Instrument air, € per Nm3 0.028 The resulting COP is strictly related to the waste gate fee.

By varying the gate fee from 130€/ton up to 150 €/ton, the

Industrial water, € per m3 0.08

resulting hydrogen cost of production range from 0.102

Cooling water, € per m3 0.014 up to 0.083 €/Nm . These values are very promising and

3

Demi water, € per m3 0.43 competitive with cop of production of conventional steam

Cost slag disposal € per ton 40 reforming process.

Cost concentrated slug disposal € per ton 200

2.2 Estimation of CO emission for

Table 6 - Assumption list for economic evaluation 2

the waste to hydrogen technology

The resulting syngas is cooled through heat recovery and For a better understanding of potential carbon footprint re-

final trim with cooling water, sent to a gal liquid separa- duction of the proposed Waste to Hydrogen technology, a

tor for the removal of condensate and routed to a PSA simplified LCA analysis has been performed.

unit. The latter allows to produce Hydrogen at purity in The use of waste as feedstock for chemical synthesis al-

order of 99.99% and a purge gas stream used as fuel in lows to fulfill at the same time two different services: from

the auxiliary boiler. A different approach may be adopted one side the recovery of waste and from the other the syn-

46 46 Impiantistica Italiana - Gennaio-Febbraio 2022