Page 49 - Impiantistica industriale

P. 49

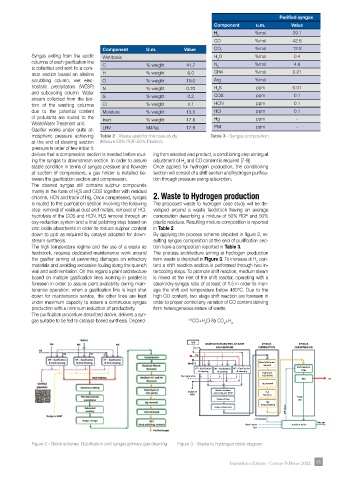

Purified syngas

Component u.m. Value

H %mol 39.1

2

CO %mol 42.6

Component U.m. Value CO 2 %mol 12.8

Syngas exiting from the acidic Wet basis H O %mol 0.4

columns of each gasifi cation line N 2 %mol 4.8

is collected and sent to a com- C % weight 41.7 2

mon section based on alkaline H % weight 6.0 CH4 %mol 0.21

scrubbing column, wet elec- O % weight 19.0 Arg %mol

trostatic precipitators (WESP) N % weight 0.70 H S ppm 0.01

2

and subcooling column. Water COS ppm 0.1

stream collected from the bot- S % weight 0.2

tom of the washing columns Cl % weight 1.1 HCN ppm 0.1

due to the potential content Moisture % weight 13.5 HCl ppm 0.1

of pollutants are routed to the Inert % weight 17.8 Hg ppm -

WasteWater Treatment unit.

Gasifi er works under quite at- LHV MJ/kg 17.9 PM ppm -

mospheric pressure achieving Table 2 - Waste used for the case study Table 3 - Syngas composition.

at the end of cleaning section (Mixture 50% RDF-50% Plastics).

pressure in order of few mbar. It

derives that a compression section is needed before rout- ing from selected end product, a conditioning step aiming at

ing the syngas to downstream section. In order to assure adjustment of H and CO content is required [7-9].

2

stable condition in terms of syngas pressure and fl owrate Once applied for hydrogen production, the conditioning

at suction of compressors, a gas holder is installed be- section will consist of a shift section and hydrogen purifi ca-

tween the gasifi cation section and compression. tion through pressure swing adsorption.

The cleaned syngas still contains sulphur compounds

mainly in the form of H S and COS together with residual

chlorine, HCN and trace of Hg. Once compressed, syngas 2. Waste to Hydrogen production

2

is routed to the purifi cation section involving the following The proposed waste to hydrogen case study will be de-

step: removal of residual dust and metals, removal of HCl, veloped around a waste feedstock having an average

hydrolysis of the COS and HCN, H S removal through an composition describing a mixture of 50% RDF and 50%

2

oxy-reduction system and a fi nal polishing step based on plastic residues. Resulting mixture composition is reported

zinc oxide absorbents in order to reduce sulphur content in Table 2.

down to ppb as required by catalyst adopted for down- By applying the process scheme depicted in fi gure 2, re-

stream synthesis. sulting syngas composition at the end of purifi cation sec-

The high temperature regime and the use of a waste as tion have a composition reported in Table 3.

feedstock, requires dedicated maintenance work around The process architecture aiming at hydrogen production

the gasifi er aiming at preventing damages on refractory from waste is depicted in Figure 3. To increase di H con-

2

materials and avoiding excessive fouling along the quench tent a shift reaction section is performed through two in-

wall and sedimentation. On this regard a plant architecture tercooling steps. To promote shift reaction, medium steam

based on multiple gasifi cation lines working in parallel is is mixed at the inlet of the shift reactor, operating with a

foreseen in order to assure plant availability during main- steam/dry-syngas ratio of at least of 1.5 in order to man-

tenance operation: when a gasifi cation line is kept shut age the shift exit temperature below 480°C. Due to the

down for maintenance service, the other lines are kept high CO content, two stage shift reaction are foreseen in

under maximum capacity to assure a continuous syngas order to proper control any variation of CO content deriving

production with a minimum reduction of productivity. from heterogeneous nature of waste.

The purifi cation procedure described above, delivers a syn-

gas suitable to be fed to catalyst-based synthesis. Depend- (1) CO+H O ßà CO +H

2 2 2

ASU

GASIFICATION AND PRELIMINARY SYNGAS SYNGAS

GAS CLEANING PURIFICATION CONDITIONING

O 2 + N 2

NG

et

a

l

h

s

/

l

C

o

ri

WASTE M Metals/Chlorine n e

removal

HT – Gasification HT – Gasification HT – Gasification Shift reaction

steps

& cleaning & cleaning & cleaning Hydrolysis

Inert granulate COS (HCN)

PSA H2

Hg removal

Sludge to Alkaline scrubber, H 2 S

WWT subcooling and WESP Removal Purge

Syngas storage gas

H 2 S

deep polishing

MP Steam

Syngas compression

Condensate

Flue gas

Demi water Auxiliary boiler

Fuel

Figure 2 - Block scheme: Gasifi cation and syngas primary gas cleaning Figure 3 - Waste to Hydrogen block diagram

Impiantistica Italiana - Gennaio-Febbraio 2022 45 45