Page 37 - Impiantistica industriale

P. 37

PC

S

202

PV PV-202

-

PT-06 PC PC V37 – 3-Way Stg Top

Purge MFC S

V20 V19 V18 V17 V16

S S S S S PV-201 PV-201

F

V15 V14 V13 V12 V11

S S S S S

S

S Storage Column mn CV-201

g

a

e

Co

to

u

l

r

V10 V9 V8 V7 V6

S S S S S

S V5 S V4 S V3 S V2 S V1 PT-07 PC

PV-203 - Backfill

S

PT-05 PT-04 PT-03 PT-02 PT-01

V38 –

V38 – 3-Way Stg Bottom PV-203

CV-202

TT-01

TT-02

Removable jacket TT-03 V-178

Col 5 Col 4 Col 3 Col 2 Col 1

TT-04 MFM F

TT-05

CWS

V36 – 3-Way OffGas

CWR

V25 V24 V23 V22 V21

S S S S S CV-104

Vacuum Pump

S V30 S V29 S V28 S V27 S V26

Set @ 11 barG

V35 V34 V33 V32 V31 SV-101

S S S S S MV-101 MFC He

Legend Symbol Description Symbol Description MFC Ch 4

Symbol Description MFC Co 2

PT Pressure Transmitter TT Temperature Transmitter

S Proportional Valve Lab-PSA R&D P&ID_2021AP-UNINA-PSA01

PC Pressure Controller 3-way Valve

S Design: Amnis Pura

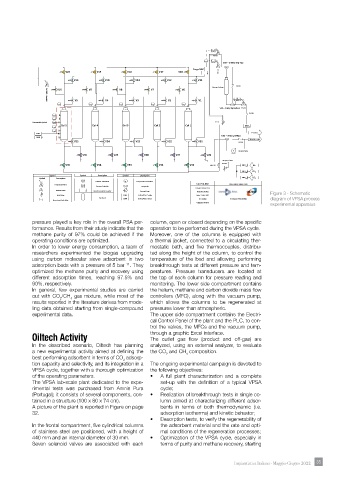

Solenoid Valve F Flow Transmiter/Controller Vacuum Pump Frederico Relvas Figure 3 - Schematic

Relief Valve CWS Cooling Water Supply Date: 21-04-2022

PSA Vessel CWR Cooling Water Return 5-Column PSAUNINA diagram of VPSA process

Non-return Check Valve H2 UNINA

experimental apparatus

Upgrade Version

pressure played a key role in the overall PSA per- column, open or closed depending on the specifi c

formance. Results from their study indicate that the operation to be performed during the VPSA cycle.

methane purity of 97% could be achieved if the Moreover, one of the columns is equipped with

operating conditions are optimized. a thermal jacket, connected to a circulating ther-

In order to lower energy consumption, a team of mostatic bath, and fi ve thermocouples, distribu-

researchers experimented the biogas upgrading ted along the height of the column, to control the

using carbon molecular sieve adsorbent in two temperature of the bed and allowing performing

adsorption beds with a pressure of 5 bar . They breakthrough tests at different pressure and tem-

11

optimized the methane purity and recovery using peratures. Pressure transducers are located at

different adsorption times, reaching 97.5% and the top of each column for pressure reading and

90%, respectively. monitoring. The lower side compartment contains

In general, few experimental studies are carried the helium, methane and carbon dioxide mass fl ow

out with CO /CH gas mixture, while most of the controllers (MFC), along with the vacuum pump,

4

2

results reported in the literature derives from mode- which allows the columns to be regenerated at

ling data obtained starting from single-compound pressures lower than atmospheric.

experimental data. The upper side compartment contains the Electri-

cal Control Panel of the plant and the PLC, to con-

trol the valves, the MFCs and the vacuum pump,

Oiltech Activity through a graphic Excel interface.

The outlet gas fl ow (product and off-gas) are

In the described scenario, Oiltech has planning analyzed, using an external analyzer, to evaluate

a new experimental activity aimed at defi ning the the CO and CH composition.

4

2

best performing adsorbent in terms of CO adsorp-

2

tion capacity and selectivity, and its integration in a The ongoing experimental campaign is devoted to

VPSA cycle, together with a thorough optimization the following objectives:

of the operating parameters. • A full plant characterization and a complete

The VPSA lab-scale plant dedicated to the expe- set-up with the defi nition of a typical VPSA

rimental tests was purchased from Amnis Pura cycle;

(Portugal); it consists of several components, con- • Realization of breakthrough tests in single co-

tained in a structure (100 x 80 x 74 cm). lumn aimed at characterizing different adsor-

A picture of the plant is reported in Figure on page bents in terms of both thermodynamic (i.e.

32. adsorption isotherms) and kinetic behavior;

• Desorption tests, to verify the regenerability of

In the frontal compartment, fi ve cylindrical columns the adsorbent material and the rate and opti-

of stainless steel are positioned, with a height of mal conditions of the regeneration processes;

440 mm and an internal diameter of 30 mm. • Optimization of the VPSA cycle, especially in

Seven solenoid valves are associated with each terms of purity and methane recovery, starting

Impiantistica Italiana - Maggio-Giugno 2022 35 35