Page 34 - Industrial Plants

P. 34

Residue Hydrocracking based on Ebullated Bed

Delayed Coking

Technology

Delayed Coker is widely diffused for its maturity, flex- Residue hydrocracking is a catalytic cracking process that utilizes ebul-

ibility and ability to handle all kind of feedstocks. lated bed reactors to simultaneously achieve the metal and CCR re-

It is a thermal cracking process that provides a moval, desulfurization and conversion reactions.

complete rejection of metals and residual carbon as

coke and provides high yields of distillates.

Main advantages Main advantages

§ Move towards zero fuel oil production. § Quality of distillates

§ Lower capital investment § Marketable low sulfur fuel oil

Main disadvantages Main disadvantages

§ Coke storage and handling environmental is- § Hydrogen consumption

sues

§ Higher capital investment

§ Coke marketing (disposal)

§ Sediment control

Installed base Installed base

On a world-scale basis, presently approximately In last 25 years there were around 20 units built based on ebullated

one-third of installed residue upgrading is by delayed bed technology installed worldwide

coking

Table 1 Residue upgrading technologies comparison

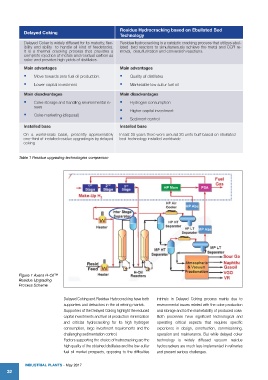

Figure 1 Axens H-Oil™

Residue Upgrading

Process Scheme

Delayed Coking and Residue Hydrocracking have both intrinsic in Delayed Coking process mainly due to

supporters and detractors in the oil refining market. environmental issues related with the coke production

Supporters of the Delayed Coking highlight the reduced and storage and to the marketability of produced coke.

capital investments and fuel oil production minimization Both processes have significant technological and

and criticize hydrocracking for its high hydrogen operating critical aspects that requires specific

consumption, large investment requirements and the experience in design, construction, commissioning,

challenging sedimentation control. operation and maintenance. But while delayed coker

Factors supporting the choice of hydrocracking are the technology is widely diffused vacuum residue

high quality of the obtained distillates and the low-sulfur hydrocrackers are much less implemented in refineries

fuel oil market prospects, opposing to the difficulties and present serious challenges.

IndustrIal Plants - May 2017

32