Page 35 - Industrial Plants

P. 35

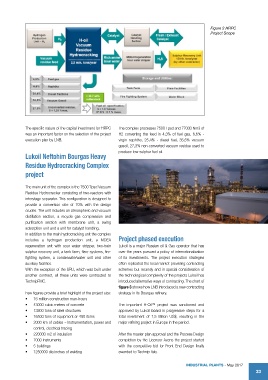

Figure 2 HRPC

Project Scope

The specific nature of the capital investment for HRPC The complex processes 7500 Tpsd and 77000 Nm3 of

was an important factor on the selection of the project H2 converting the feed in 4,3% of fuel gas, 6,6% -

execution plan by LNB. virgin naphtha, 25,4% - diesel fuel, 35,5% vacuum

gasoil, 27,3% non-converted vacuum residue used to

produce low-sulphur fuel oil.

Lukoil Neftohim Bourgas Heavy

Residue Hydrocracking Complex

project

The main unit of the complex is the 7500 Tpsd Vacuum

Residue Hydrocracker consisting of two-reactors with

interstage separator. This configuration is designed to

provide a conversion rate of 70% with the design

crudes. The unit includes an atmospheric and vacuum

distillation section, a recycle gas compression and

purification section with membrane unit, a swing

adsorption unit and a unit for catalyst handling.

In addition to the main hydrocracking unit the complex

includes a hydrogen production unit, a MDEA Project phased execution

regeneration unit with sour water stripper, two-train Lukoil is a major Russian oil & Gas operator that has

sulphur recovery unit, a tank farm, flare systems, fire- over the years pursued a policy of internationalization

fighting system, a condensate/water unit and other of its investments. The project execution strategies

auxiliary facilities. often replicated the local market prevailing contracting

With the exception of the SRU, which was built under schemes but recently and in special consideration of

another contract, all these units were contracted to the technological complexity of the projects Lukoil has

TechnipFMC. introduced alternative ways of contracting. The chart of

figure 3 shows how LNB introduced a new contracting

Few figures provide a brief highlight of the project size: strategy in its Bourgas refinery.

• 16 million construction man-hours

• 43000 cubic meters of concrete The important H-Oil™ project was sanctioned and

• 13800 tons of steel structures approved by Lukoil board in progressive steps for a

• 16500 tons of equipment or 490 items total investment of 1,5 Billion US$, resulting in the

• 2000 km of cables – Instrumentation, power and major refining project in Europe in the period.

control, electrical tracing

• 220000 m2 of insulation After the master plan approval and the Process Design

• 7000 Instruments completion by the Licensor Axens the project started

• 5 buildings with the competitive bid for Front End Design finally

• 1250000 dia inches of welding awarded to Technip Italy.

IndustrIal Plants - May 2017

33