Page 37 - Impiantistica Industriale

P. 37

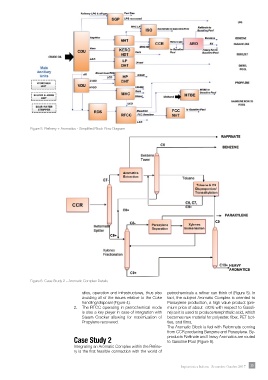

Figure 5. Refi nery + Aromatics - Simplifi ed Block Flow Diagram

Figure 6. Case Study 2 – Aromatic Complex Details

stics, operation and infrastructures, thus also petrochemicals a refi ner can think of (Figure 5). In

avoiding all of the issues relative to the Coke fact, the subject Aromatic Complex is oriented to

handling/disposal (Figure 4). Paraxylene production, a high value product (pre-

2. The RFCC operating in petrochemical mode mium price of about +30% with respect to Gasoli-

is also a key player in case of integration with ne) as it is used to produce terephthalic acid, which

Steam Cracker allowing for maximization of becomes raw material for polyester, fi ber, PET bot-

Propylene recovered. tles, and fi lms.

The Aromatic Block is fed with Reformate coming

from CCR producing Benzene and Paraxylene. By-

Case Study 2 products Raffi nate and Heavy Aromatics are routed

to Gasoline Pool (Figure 6).

Integrating an Aromatic Complex within the Refi ne-

ry is the fi rst feasible connection with the world of

Impiantistica Italiana - Settembre-Ottobre 2017 35