Page 38 - Impiantistica Industriale

P. 38

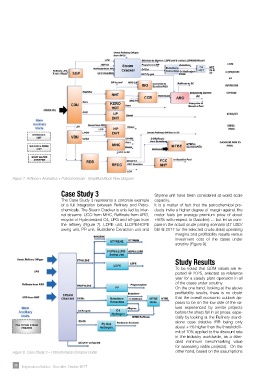

Figure 7. Refi nery+ Aromatics + Petrochemicals - Simplifi ed Block Flow Diagram

Case Study 3 Styrene unit have been considered at world scale

The Case Study 3 represents a concrete example capacity.

of a full integration between Refi nery and Petro- It is a matter of fact that the petrochemical pro-

chemicals. The Steam Cracker is only fed by inter- ducts invite a higher degree of margin against the

nal streams: UCO from MHC, Raffi nate from ARO, motor fuels (an average premium price of about

recycle of Hydrotreated C4, LPG and off-gas from +50% with respect to Gasoline) … but let us com-

the refi nery (Figure 7). LDPE unit, LLDPE/HDPE pare in the actual crude pricing scenario (47 USD/

swing unit, PP unit, Butadiene Extraction unit and bbl @ 2017 for the selected crude slate) operating

margins and profi tability results versus

investment cost of the cases under

scrutiny (Figure 9).

Study Results

To be noted that GOM values are re-

ported @ 2025, selected as reference

year for a steady plant operation in all

of the cases under scrutiny.

On the one hand, looking at the above

profi tability results, there is no doubt

that the overall economic outlook ap-

pears to be on the low side of the va-

lues experienced by similar projects

before the sharp fall in oil prices, espe-

cially by looking at the Refi nery stand-

alone case (relative IRR being only

about +1% higher than the threshold li-

mit of 10% applied to the discount rate

in the industry worldwide, as a stan-

dard minimum benchmarking value

for assessing viable projects). On the

Figure 8. Case Study 3 – Petrochemical Complex Detail other hand, based on the assumptions

36 Impiantistica Italiana - Settembre-Ottobre 2017