Page 14 - Impiantistica industriale

P. 14

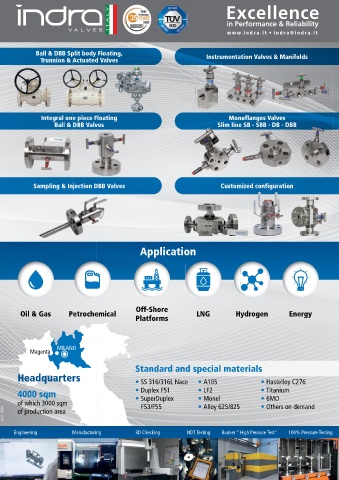

Excellence

in Performance & Reliability

www.indra.it indra@indra.it

Ball & DBB Split body Floating, Instrumentation Valves & Manifolds

Trunnion & Actuated Valves

Integral one piece Floating Monoflanges Valves

Ball & DBB Valves

Ball & DBB Valves Slim line SB - SBB - DB - DBB

Customized configuration

Sampling & Injection DBB Valves Customized configuration

Application

1

:

0/

0

0

1 PRODUCT

2

U

01

RPED 2014/68/EU

1

PA

0

T

-

2

5

EAC-CU

5

Y

EAC- 01

PRODUCT afe

COMPANY

T

N

R

T

C

EAC-CU-TR 010/2011

e

N

-

COMPANY I EN ISO 9001:2015U-TR 010/2011

COMPANY COMPA COM COMPANY N ISO 9001:2015 UNI EO 9 UNI EN ISO 9001:2015 PRODUC PRODUC T Fi r e S Fire Saf Fire U Fire Safe Safe EAC-C UNI EN ISO 9001:2015 PRODUCT 2 01 1 PED 2 PRODUCT Safe /68/EUPED 2014/68/EU014/68/EU CONSTRUCTION CON ASME/ANS EAC-CU-TR 010/2011/ANSI B16.34ASME/ANSI B16.34ASME/ANSI B16.34 EAC-CU-TR 010/2011 MA CONSTRUCTION SS 316/316L, SS 316/316L, SS 316/316L, API 598 API 598 MATERIALS SS 316/316L, SS 316/316L,

API 5

PED 2014/68/EU

API 598

8 MATERIALS

9

I E

Fire Safe CONSTRUCTION CONSTRUCTION STRUCTION I B16.34

API 598

API 598

ASME

CONSTRUCTION

ASME/ANSI B16.34

MATERIALS

ASME/ANSI B16.34

N

PED 2014/68/EUERIALSMATERIALSTERIALSSS 316/316L,

MAT

U

Y

1

S

1

0

01

2

0/

:

O 9

0

Fi PED 2014

e

UNI EN I

N

S

N I

0

r

S

I

O 1

TI

4

S

9

0

O

TI

N

A

CERTIFICATIONS

TI

C

N

O

S

C

S

A

N

O

F

I

s

u

e

o

r

i

n

t

n

CERTIFICATIONS

For Eu

A

r

i

t

C C

For EAC Countries

NORMS & Duplex F51, SuperDuplex

7

NORMS &

NORMS &

Duplex F51, SuperDuplex

I

S

e

s

4

9

O 1

0

A

I 6

9

P

4

–

7

7

0

ISO 104

CERTIFICATIONS

7

–

7

0

ISO 1A

9

–

A

7

F

I 6

F

A

P

P

A

A

–

I 6

0

I 6 For EAC Coun

P

TI

CERTIFICATIONS CERTIFI CERTI CERTIFICATIONS CERTIFICATIONS CERTIFI CERTI CERTIFICATIONSAPI 607–API 6FA – ISO 10497–API 607–API 6FAtries For EAC C o For EAC Countries CERTIFICATIONS–API 607–API 6FA NORMS & NORMS & NORMS & ISO 10497–API 607–API 6FA For EAC Countries Duplex F51, SuperDuplex Duplex F51, SuperDuplex Duplex F51, SuperDuplex Duplex F51, SuperDuplex

S

A

A

O

N

I

C

F

C

N ASME/ANSI B1.20.11.20.1

ASME/ANSI B

ASME/ANSI B1.20.1

API 6D

ASME/ANSI B1.20.1

API

/

0

7

0

/

8

0

:

1

E

1

0

4

1

A

1

0

S 1

REGULATIONS

4

2

20

:

L

N

S

T

A

O

E

U

/

I

T

I

0

7

0

2

U

4

O

S

4REGULATIONS

/3

2

7

BS OHSAS 18001 BS OHS BS OS 1 BS OHSAS 18001:2007 BS OHSAS 18001:2007 BS OHSAS 18001:2007 ATEX 2014/34/EU ATEX 20 ATEX/3 ATEX 2014/34/EU REGULA REGU REGULATIONS ASME ASME/ANSI B1.20.1 API 6DAPI 6D 6D A NS I B 1 . 20 1 . ATEX 2014/34/EU ATEX 2014/34/EUIONS F53/F55, F53/F55, F53/F55, REGULAT F53/F55, API 6D API 6D F53/F55, F53/F55,

0

8

0

0

:

H

S

A

a

n

EAC-CU-TR 012/2011

a

s

n

s

y

i

n

t

a

g

eme

a

g

Health

M

2

/

C

Health & Safety M Health &eme n f Health & Safety Management Fugitive Emission Fugitive Fugit Emi Fugitive Emission Health & Safety Management011EAC-CU-TR 012/2011 012/2011 EAC- EAC-CU-TR 012/2011 Fugitive Emission Fugitive Emission EAC-CU-TR 012/2011 NS . 5 I B 1 6 . API 602 API 6 API 602 A105, LF2, A105, LF2, A105, LF2, API 602 API 602 A105, LF2, A105, LF2,

A105, LF2,

U

T

R

01

2

-

t

io

n EAC-CU-TR

n

t

g

n

t

n

eme

a

Health & Safety Manageme

n

M

e

e

Sa

io

Sa

t

f

e

s

&

t

v

Emi

a

y

s

A

6

2

5

1

ASME/A API 6

5

ASME/ANSI B16.

ASME/ANSI B16.5

ASME B

ASME/ANSI B16.5

/02

NS

I

0

ASME/ANSI B16.5

EN ISO 15848-1 EN ISO 1 EN IS 4 EN ISO 15848-1 For EAC Countries For EAC C o For EAC Countries CRN for C a n CRN for Canada EN ISO 15848-1 For EAC Countries For EAC Countriesanada CRN for Canada Monel, Monel, Monel, Monel, Monel,

EN ISO 15848-1

8

o

a

A

1

1

s

8

CRN f

-

8

d

a

For Eu

a

5

a

r C

d

n

a

Monel,

e

n

u

4

t

r

CRN for C

oCRN for Canada

s

e

5

8

i

C C

i

O 1

r

t

-

n

3Alloy 625/Incoloy 825, C-276,

0

-

0

UNI EN ISO 1400 1 UNI EN I UNI EO 1 UNI EN ISO 14001:2015 EN ISO 15848-2 EN ISO 1 EN IS 4 EN ISO 15848-2 UNI EN ISO 14001:2015 EN ISO 15848-2 EN ISO 15848-2 ASME V NA ASME VIII75 / MR 01-03 R 0 1 NACE MR 01-75 / MR 01-03 Alloy 625/Incoloy 825, C-276, NACE MR 01-75 / MR 01-03 NACE MR 01-75 / MR 01-03 Alloy 625/Incoloy 825, C-276,

0

-

1

R 0

S

Alloy 625/Incoloy 825, C-276,

4

O 1

5 / M

1

Alloy 625/Incoloy 825, C-276,

7

0

Alloy 625/Incoloy 825, C-276,

ASME VIII

-

5

0

N I

5 / M

III

R 0

V

0

R 0

1

1

5

1

NACE M

0

4

2

2

1

:

1

UNI EN ISO 14001:2015

NACE M

8

8

:

:

-

5

-

2

-

ASME VIII

7

5

4

0

5

3

O 1

8

III

0

8

2

E

2

ASMCE MR 01-

ASME VIII

S

1

t

-

T

EAC-CU-TR

CU

a

g

l

a

n

n

t

M

a

t

g

n

eme

a

n

a

a

g

Envirnt

n

Environmental M Environeme n Environmental Management Environmental Manageme n Environmental Management2013EAC-CU-TR 032/2013 032/2013 EAC- EAC-CU-TR 032/2013 EAC-CU-TR 032/2013 EAC-CU-TR 032/2013 Titanium, Titanium, Titanium, Titanium, Titanium,

Titanium,

a

me

l

me

M

n

t

o

a

eme

/

t

n

R

03

2

6

E

ASME B16.10

.

ASME B16.10 Norsoksok

ASME B16.10

Norsok

ASM10

ASME B1 Nor

Norsok

u

n

r

i

o

e

s

t

s

e

For Eu

For EAC Countrie For EAC C o For EAC Countries ASME B16.10 For EAC Countries B1 6 . 10 For EAC Countries 6MO, 6MO, 6MO, 6MO, Norsok Norsok 6MO, 6MO,

s

i

t

C C

r

A

n

Others on demand

Others on demand Others on demand Others on demand Others on demand

Others on demand

L & D

A

T

O

D

B

I

NS

N

I

I

N

N

L

E

O

B SP

Y F

G

N & A

I

N

N

E F

T

E P

U

E

B V

T

T

NS

B

A

I

O

R

A

, T

R

G

T

R

A

T

G B

U

L O

R

L & D

MEN

I

A

U

L

I

L

G

B V

A

I

B

L

A

A

L

V

E

S

D

O

A

R

L

B

L & D

B V

, T

L

T B

E

I

Y F

V

L

C

T

V

I

B SP

O

L

I

E

B

R

N

A

N

I

A

E

O

S

E F

C

T

L

T

T B

N & A

I

F

O

A

A

N

I

L

A

L

I

N

O

D

S & M

L

A

N V

O

E

I

S & M

S

V

E

A

D

L

F

S

BALL & DBB SPLIT B

V

U

L

A

L

T

BALL & DBB SP L I T B O BALL & DBB SPLIT BODY FLOATING, TRUNNION & ACTUATD V E E D V V A E L S V E S BALL & DBB SPLIT BODY FLOATING, TRUNNION & ACTUATED VALVESL & DBB VALVES INTEGRAL ONE PIEC INTEGRAL ONE PIECE FLOATING BALL & DBB VALVESALVES & MANIFOLDS INSTRUMENTATION V A L V E S & M A N I F O L D S

A

BALL & D

E

A

D V

C

L

Y F

S

O

S

T

O

E

T

D

D

S

O

T

S

L

A

NS

R

U

T

MEN

A

N

V

T

T

G

L

E

NS

N V

U

MEN

I

T

E

N

V

I

E

A

N

BAL

I

O

A

L

V

F

I

N V

T

I

T

T

I

MEN

R

S & M

U

O

T

A

INSTRUMENTATION VALVES & MANIFOLDS

T

N V

A

I

C

E

L

T

N

S

R

I

I

T

O

N

N

E F

B

O

R

E F

U

A

A

O

N

L O

U

E

N

L O

N & A

E

I

R

E

N

N

N

R

L

C

N

T

T

A

D V

I

U

O

T

T

O

A

G

O

I

N & A

L

I

A

A

G

A

T

N

T

A

B V

, T

G B

E

, T

L & D

A

U

T

N

N

E

A

D V

A

L & D

I

L

E

V

I

I

L

G B

N

D

O

C

E P

U

G

E F

L

E

A

A

N

G B

S

C

Y F

N

L O

L

G B

A

L

T

E P

L

O

O

C

G

I

A

L

I

V

E P

T

N

N

CONNECTIONS

CONNECTIONS

I

T

• ASME Class – 150lb to 2500lb

ON

S

• ASME Class – 150lb to 2500lb • ASME Class – 150lb to 2500lb • ASME Class – 150lb to 2500lb CON N CONNECTIONS CONNECTIONS CONNECTIONS CONNE C CONON E S C T I ON S CONNECTIONS CONNECTIONS

C

T

• ASME Class – 150lb to 2500lb

I

E

• ASME Class – 150lb to 2500lb CONNECTIONSCONNECTIONS

From 1

/

10000

5000

• API 3000/5000 • API 3000 / • API 3000/5000/10000 • API 3000/5000/10000 • API 3000/5000/10000 From 1/2” to 8” From 1/2” to 8” From 1/2” to 8” From 1 /8” to 2” From 1 /8” to 2” From 1 /8” to 2”/8” to 2” From 1 /8” to 2” From 1 /8” to 2”

/

From 1/2” to 8”

10000

/

From 1/2” to 8”

5000

/

10000

From 1/2” to 8”

• API 3000

, SW

, BW

, BSPT

NPT, BSPP, BSPT, BW, SW

, SW

• Size – 1/2” to 8” (FB & RB) • Size – 1/2” to 8” (FB & RB) • Size – 1/2” to 8” (FB & RB) • Size – 1/2” to 8” (FB & RB) Threaded Threaded Threaded Threaded NPT, BSPP, BSPT, BW NPT, BSPP NPT, BSPP , BSPT , BW , SW NPT, BSPP, BSPT, BW, SW NPT, BSPP, BSPT, BW, SW

• Size – 1/2” to 8” (FB & RB)

Threaded

• Size – 1/2” to 8” (FB & RB)

Threaded

Flanged

• Soft Seated & Metal Seated

• Soft Seated & Metal Seated

• Soft Seated & Metal Seated • Soft Seated & Metal Seated • Soft Seated & Metal Seated • Soft Seated & Metal Seated FlangedFlanged Flanged Petrochemical Off-Shore FlangedFlanged Welded (BW or SW) LNG Hydrogen Energy

G

W

Oil & Gas Welded (BW or SW)Welded (BW or SW)Welded (BW or SW)elded (BW or SW)

, Gearbox or Actuated

• Lever

• Lever, Gearbox or Actuated • Lever, Gearbox or Actuated • Lever, Gearbox or Actuated • Lever, Gearbox or Actuated Welded (BW or SW) RATING RATING RATIN RATING RATING RATING

• Lever, Gearbox or Actuated

6.000 - 10.000 PSI (threaded types)

6.000 - 10.000 PSI (threaded types)

eaded types)

6.000 - 10.000 PSI (thr

6.000 - 10.000 PSI (thr

• Temperatur

e Range -46°C to +240°C

Hub

• Temperature Range -46°C to +240°C e Range -46°C to +240°C • Temperature Range -46°C to +240°C Hub Platforms Hub 6.000 - 10.000 PSI (thr eaded types) eaded types) 6.000 - 10.000 PSI (threaded types)

• Temperature Range -46°C to +240°C HubHubHub

• Temperature Range -46°C to +240°C

• Temperatur

SCH. 40, 80, 160, XXS (BW-SW version)

SCH. 40, 80, 160, XXS (BW-SW version)

SCH. 40, 80, 160, XXS (BW-SW version)

SCH. 40, 80, 160, XXS (BW-SW version)

• High Temperatur

emperatur

e on demand

• High Temperature on demand

• High Temperatur • High Te on demand • High Temperature on demand • High Temperature on demand SCH. 40, 80, 160, XXS (BW-SW version) SCH. 40, 80, 160, XXS (BW-SW version)

e on demand

• Low Temperature on demandRATING RATING

• Low Temperatur • Low Te on demand • Low Temperature on demand • Low Temperature on demand RATIN RATING RATING RATING

e on demand

• Low Temperatur

G

e on demand

emperatur

E

N

T

ASME Class – 150lb to 2500lb

ASME Class – 150lb to 2500lb

ASME Class – 150lb to 2500lb ASME Class – 150lb to 2500lb ASME Class – 150lb to 2500lb ASME Class – 150lb to 2500lb BONNET BONNET BON BONNET BONNET BONNET

Screwed, O.S.&Y

Screwed, O.S.&Y. Bolted, Antitamper,

Screwed, O.S.&Y. Bolted, Antitamper,

/

/

10000

API 300015000

API 3000/5000/10000 / API 3000 / 10000 / / 15000 / 15000 API 3000/5000/10000/15000 API 3000/5000/10000/15000 Screwed, O.S.&Y. Bolted, Antitamper, Screwed, O.S.&Y. Bolted, Antitamper, . Bolted, Antitamper , Screwed, O.S.&Y. Bolted, Antitamper ,

API 3000/5000/10000/15000

5000

5000

Extended Locking device, Cryogenic service

Extended Locking device, Cryogenic service

Extended Locking device, Cryogenic service

Extended Locking device, Cryogenic service Extended Locking device, Cryogenic service

Extended Locking device, Cryogenic service

DESIGN DESIGN DESI G DESIGN DESIGN DESIGN

N

A

N

L

B

M L

V

B

F

B - D

B

B

N

M L

B

N

A

L

I

E

B

L

V

E V

A

I

G

M L

N

B - D

E S

O

S – S

A

S – S

B - S

L

I

I

E V

F

B - D

B - S

G

M L

S – S

E

B

L

I

B

N

I

B - D

E V

B - S

B

V

B - S

I

E S

E

E S

B - D

L

B - D

I

MONOFLANG

L

N

L

S – S

B - D

E S

B - D

A

B

B

N

B

Single or Double Block with Single or Double Block with Single or Double Block with Single or Double Block with MONO MOLE MONOFLANGE VALVES – SLIM LINE SB - SBB - DB - DBB MONOFLANGE VALV MONOFLANGE VALVES – SLIM LINE SB - SBB - DB - DBB

Single or Double Block with

Single or Double Block with

optional Bleed (SB-SBB-DB-DBB)

optional Bleed (SB-SBB-DB-DBB)

optional Bleed (SB-SBB-DB-DBB) optional Bleed (SB-SBB-DB-DBB) optional Bleed (SB-SBB-DB-DBB) optional Bleed (SB-SBB-DB-DBB)

Integral Ball Design: Soft & Metal Seat

Integral Ball Design: Soft & Metal Seat

Integral Ball Design: Soft & Metal Seat Integral Ball Design: Soft & Metal Seat CONNECTIONS CONNE CONON E S C T I ON S CONNECTIONS CONNECTIONS

Integral Ball Design: Soft & Metal Seat

Integral Ball Design: Soft & Metal Seat

T

I

C

MILANO

N

CONNECTIONS

Inlet: 1/2” to 4” flanged

Inlet: 1/2” to 4” flanged

T

T

BONNET BONNE BON N BONNET BONNET BONNET Inlet: 1/2” to 4” flanged Inlet: 1/2” to 4” flanged Inlet: 1/2” to 4” flanged Inlet: 1/2” to 4” flanged

E

Outlet: Threaded & Flanged

Outlet: Thr

Outlet: Threaded & Flanged

Outlet: Threaded & Flanged

Outlet: Threaded & Flanged

eaded & Flanged

Outlet: Threaded & Flanged

Screwed, O.S.&Y Screwed, O.S.&Y. Bolted, Screwed, O.S.&Y. Bolted,

Magenta Screwed, O.S.&Y. Bolted, Screwed, O.S.&Y. Bolted, Screwed, O.S.&Y. Bolted, . Bolted,

Antitamper, Extended Locking device,

Antitamper, Extended Locking device,

Antitamper, Extended Locking device, , Extended Locking device, Antitamper, Extended Locking device, RATING RATING RATIN RATING RATING RATING

Antitamper, Extended Locking device,

Antitamper

G

Cryogenic service

Cryogenic service

ASME Class – 150lb to 2500lb

ASME Class – 150lb to 2500lb

Cryogenic service Cryogenic service Cryogenic service Cryogenic service ASME Class – 150lb to 2500lb ASME Class – 150lb to 2500lb ASME Class – 150lb to 2500lb

ASME Class – 150lb to 2500lb

10000

10000

/

5000

API 3000/5000/10000

5000

API 3000

API 3000/5000/10000

API 3000/5000/10000

/

/

/

API 3000/5000/10000

API 3000

Standard and special materials BONNET BONNET

BON

BONNET

T

BONNET

N

BONNE

E

T

J

C

T

,

B

E

N

G & I

I

SAMPLING & I N J E C SAMO SAMPLING & INJECTION DBB VALVES SAMPLING & INJECT SAMPLING & INJECTION DBB VALVES . Bolted, Antitamper , Screwed, O.S.&Y. Bolted, Antitamper ,

A

B V

N

L

V

Screwed, O.S.&Y. Bolted, Antitamper,

T

A

A

E

Screwed, O.S.&Y

A

N D

S

E

S

I

G & I

V

SAMP

B Screwed, O.S.&Y. Bolted, Antitamper,

B V

N D

O

I

L

P

L

N D

L

B V

B

L

I

V

E

. Bolted, Antitamper

N D

N

E

S

E

N

L

J

O

I

V

C

I

T

B

O

Screwed, O.S.&Y

B V

Screwed, O.S.&Y. Bolted, Antitamper,

S

Headquarters These DBBs are used for sampling & Injection Extended Optional locking device, Extended Optional locking device, Extended Optional locking device,

Extended Optional locking device,

Extended Optional locking device,

Extended Optional locking device,

Cryogenic service

Cryogenic service

Cryogenic service

Cryogenic service

Cryogenic service

Cryogenic service

e used for sampling & Injection

These DBBs ar

e used for sampling & Injection

These DBBs are used for sampling & Injection

These DBBs are used for sampling & Injection

These DBBs ar

These DBBs are used for sampling & Injection

purpose and for further analysis of the process.

purpose and for further analysis of the pr

purpose and for further analysis of the pr

purpose and for further analysis of the process.

ocess.

purpose and for further analysis of the pr

purpose and for further analysis of the pr ocess. ocess. ocess. SS 316/316L Nace A105 Hastelloy C276

A

R

O

G

T

U

N

Valves are designed with Integral Body and CUSTOMIZED CONFIGURATIONCUSTOMIZED CONFIGURATIONCUSTOMIZED CONFIGURATIONCUSTOMIZED CONFIGURATION

I

Valves are designed with Integral Body and

e designed with Integral Body and

Valves are designed with Integral Body and obe (Not W elded). Valves are designed with Integral Body and CUSTOMIZED CONF I CUSTOMIZED CONFIGURATION

Valves ar

Valves are designed with Integral Body and

LF2

elded).

Integral Sampling Probe (Not Welded).

Integral Sampling Pr

elded).

Integral Sampling Probe (Not Welded).

Integral Sampling Pr

elded).

Integral Sampling Pr

obe (Not W

obe (Not W

Integral Sampling Probe (Not W

4000 sqm Duplex F51 Probe length is defined in acc. to the application Titanium

Probe length is defined in acc. to the application

Probe length is defined in acc. to the application

Probe length is defined in acc. to the application

Probe length is defined in acc. to the application

Probe length is defined in acc. to the application

requirements and the pipeline diameter - upon

requir

ements and the pipeline diameter - upon

requirements and the pipeline diameter - upon

requirements and the pipeline diameter - upon

requirements and the pipeline diameter - upon

requirements and the pipeline diameter - upon

indication. Indra can supply Wake Frequency

indication. Indra can supply W ake Fr equency ake Fr equency equency SuperDuplex equency Monel 6MO

indication. Indra can supply W

ake Fr

indication. Indra can supply W

indication. Indra can supply Wake Frequency

indication. Indra can supply W

ake Fr

and Bending Stress Calculations to ensure

e

and Bending Str

and Bending Stress Calculations to ensure

and Bending Str

ess Calculations to ensur

and Bending Stress Calculations to ensur

of which 3000 sqm obe Length and e and Bending Stress Calculations to ensur e Alloy 625/825 Others on demand

e

ess Calculations to ensur

obe Length and

the correct selection of the Probe Length and

the correct selection of the Probe Length and

the corrobe Length and

the correct selection of the Probe Length and

the correct selection of the Pr

the correct selection of the Pr

ect selection of the Pr

F53/F55

the valve optimum performance in time.

the valve optimum performance in time.

the valve optimum performance in time.

the valve optimum performance in time.

the valve optimum performance in time.

the valve optimum performance in time.

rev.0 - 2020 of production area

t

s

in

e

g

s

e

re

n

T

T

u

s

t

1

e T

r

s

g

u

in

in

e

t

t

100% Pressure Testing

”

s

g

n

n

NDT NDT Testing

i

i

e

i

n

r

g

e

i

t

n

g

B

s

Te

n

e

e

g

g

a

ng

Engineering

r

i

i

c

t

u

ng

r

f

a

ng

3D Checking 3D Checking

Manufacturing 3D Checking3D Checking

c

u

f

u

Engineering

t

u

Engineering Engin Engi r Engineering Manufacturi Manu Man Manufacturing Engineering Manufacturing Manufacturing 3D Ch e c k i n g NDT Testing NDT Te s t NDT Testinger “ 3D CheckingBunker “High Pressure Test” Bunker “High Pressure Test” Bunker “High Pressure Test” High Pressure Test” 100 NDT Testing 100% NDT Testingker “High Press Bunker “High Pressure Test” 00% Pressure Testing

%

re

re

P

g

10

s

s

0

B

u

s

u

re

e

T

P

s

re

s

re

re

P

s

1 100% Pressure Testing

s

%

n

u

k

3D Checking

Bunker “ High Pressure Test”

P

e

s

in

t

%

0

u

re

T

0