Page 55 - Industrial plants

P. 55

blowing cleanings, allowed to achieve uninterrupted supervision itself is aimed at the better management of

operation period more than 8000 hours/year. the interventions on the plants both under normal

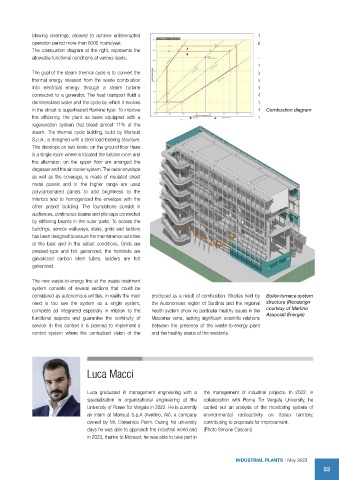

The combustion diagram at the right, represents the conditions and under failure.

allowable functional conditions at various loads. Data collected during time demonstrate that waste-to-

energy plants, including the Macomer one, have an

The goal of the steam thermal cycle is to convert the environmental impact around eight times less than a

thermal energy released from the waste combustion normal landfill. However, waste-to-energy plants are

into electrical energy through a steam turbine not a zero impact solution. The emission of CO2 and

connected to a generator. The heat transport fluidi s other dangerous substances produced at the end of

demineralized water and the cycle by which it evolves waste treatment, represent a danger to both health

in the circuit is superheated Rankine type. To improve and environment. One of the main disadvantages of Combustion diagram

the efficiency, the plant as been equipped with a waste-to-energy is related to the fumes and ash

regeneration system that bleed almost 11% of the

steam. The thermal cycle building, build by Monsud

S.p.A., is designed with a steel load-bearing structure.

This develops on two levels: on the ground floor there

is a single room where is located the turbine room and

the alternator; on the upper floor are arranged the

degasser and the air-cooler system. The outer envelope

as well as the coverage, is made of insulated sheet

metal panels and in the higher range are used

polycarbonated panels to add brightness to the

interiors and to homogenized the envelope with the

other project building. The foundations consist in

audiences, continuous beams and pile caps connected

by stiffening beams in the outer parts. To access the

buildings, service walkways, stairs, grids and ladders

has been designed to ensure the maintenance activities

at the best and in the safest conditions. Grids are

pressed-type and hot galvanized, the handrails are

galvanized carbon steel tubes, ladders are hot

galvanized.

The new waste-to-energy line at the waste treatment

system consists of several sections that could be

considered as autonomous entities, in reality the main produced as a result of combustion. Studies held by Boiler-furnace system

need is too see the system as a single system, the Autonomous region of Sardinia and the regional structure (Renderign

complete ad integrated especially in relation to the health system show no particular healthy issues in the courtesy of Martino

functional aspects and guarantee the continuity of Macomer zone, lacking significant scientific relations Associati Energia)

service. In this context it is planned to implement a between the presence of the waste-to-energy plant

control system where the centralized vision of the and the healthy status of the residents.

Luca Macci

Luca graduated in management engineering with a the management of industrial projects. In 2022, in

specialization in organizational engineering at the collaboration with Roma Tor Vergata University, he

University of Rome Tor Vergata in 2022. He is currently carried out an analysis of the monitoring system of

an intern at Monsud S.p.A (Avellino, AV), a company environmental radioactivity on Italian territory,

owned by Mr. Domenico Pierni. During his university contributing to proposals for improvement.

days he was able to approach the industrial world and (Photo Simone Casconi)

in 2023, thanks to Monsud, he was able to take part in

IndustrIal Plants - May 2023

53