Page 78 - Industrial plants

P. 78

minimum required specific gravity (Picture 6).

Hydrogen Pipelines Offshore

As far as the occurrence of cyclic loads for offshore

The offshore pipeline Oil and Gas industry designed pipelines, the high longitudinal stress and strain due to

using a stress-based approaches till the 90’s when a the installation phase (Picture 7), to the sea bottom

dedicated R&D project - SUPERB JIP - introduced in unevenness and to the environmental loads need to be

DNV-ST-F101 (former DNV ’96) the “limit state” design verified against the impact of the presence of Hydrogen

approach. Since then, the design by failure mode is the on the resistance of pipe materials and welds to

basis for the offshore pipeline design and relevant fatigue.

safety factors are calibrated through structural reliability Fatigue damage is accumulated since the installation

theory based on acceptable target failure rates. The phase because of weather condition and depending

transportation of H , or H /NG through existing or on on dynamic response of the pipe-vessel system. Also,

2 2

purpose designed pipelines can cause additional the fatigue in operating conditions is caused by

failure modes or important changes on the failure environmental loads originating bending stress cycles

modes mechanisms with respect to the typical with frequencies of the order of less than one hertz

occurring to submarine pipelines according to DNV- joined with long cycles temperature and pressure

ST-F101. It is, therefore, required that a combined variations.

assessment is done, and cross correlation(s)

established among failure modes, material properties,

usual and typical loads of the new energy scenarios

and the specific fluid (e.g. H or H /NG) environment

2 2

(Torselletti et al., OMC-2021).

Hydrogen presents some unique “degradation

mechanisms” to be considered during design. It has an

interaction with typical offshore high strength line pipe

materials (e.g. API 5L X60, X65, X70) and pipe welds,

affecting key properties such as ductility, toughness

and fatigue performance. A dedicated Saipem Offshore

Engineering Team analyzed these issues considering all

typical failure modes applicable to an offshore pipeline.

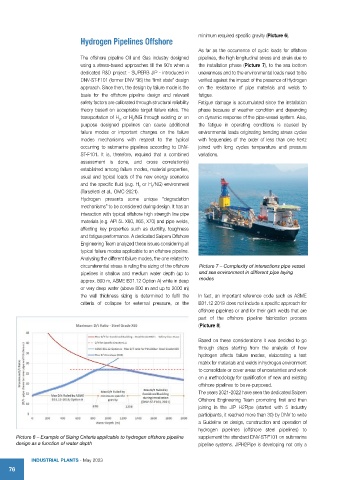

Analysing the different failure modes, the one related to

circumferential stress is ruling the sizing of the offshore Picture 7 – Complexity of interactions pipe vessel

pipelines in shallow and medium water depth (up to and sea environment in different pipe laying

approx. 800 m, ASME B31.12 Option A) while in deep modes

or very deep water (above 800 m and up to 2000 m)

the wall thickness sizing is determined to fulfil the In fact, an important reference code such as ASME

criteria of collapse for external pressure, or the B31.12 2019 does not include a specific approach for

offshore pipelines or and for their girth welds that are

part of the offshore pipeline fabrication process

(Picture 8).

Based on these considerations it was decided to go

through steps starting from the analysis of how

hydrogen affects failure modes, elaborating a test

matrix for materials and welds in hydrogen environment

to consolidate or cover areas of uncertainties and work

on a methodology for qualification of new and existing

offshore pipelines to be re-purposed.

The years 2021-2022 have seen the dedicated Saipem

Offshore Engineering Team promoting first and then

joining in the JIP H2Pipe (started with 5 industry

participants, it reached more than 30) by DNV to write

a Guideline on design, construction and operation of

hydrogen pipelines (offshore steel pipelines) to

Picture 6 – Example of Sizing Criteria applicable to hydrogen offshore pipeline supplement the standard DNV-ST-F101 on submarine

design as a function of water depth pipeline systems. JIPH2Pipe is developing not only a

IndustrIal Plants - May 2023

76