Page 73 - Industrial plants

P. 73

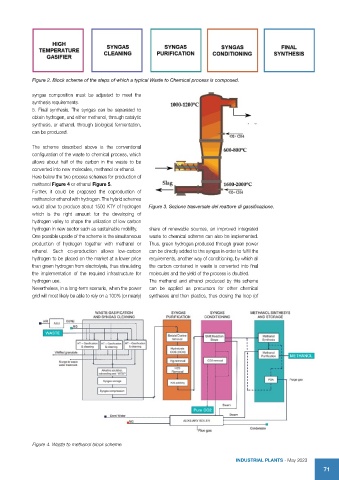

Figure 2. Block scheme of the steps of which a typical Waste to Chemical process is composed.

syngas composition must be adjusted to meet the

synthesis requirements.

5. Final synthesis. The syngas can be separated to

obtain hydrogen, and either methanol, through catalytic

synthesis, or ethanol, through biological fermentation,

can be produced.

The scheme described above is the conventional

configuration of the waste to chemical process, which

allows about half of the carbon in the waste to be

converted into new molecules, methanol or ethanol.

Here below the two process schemes for production of

methanol Figure 4 or ethanol Figure 5.

Further, it could be proposed the coproduction of

methanol or ethanol with hydrogen. The hybrid schemes

would allow to produce about 1500 KTY of hydrogen Figure 3. Sezione trasversale del reattore di gassificazione.

which is the right amount for the developing of

hydrogen valley to shape the utilization of low carbon

hydrogen in new sector such as sustainable mobility. share of renewable sources, an improved integrated

One possible upside of the scheme is the simultaneous waste to chemical scheme can also be implemented.

production of hydrogen together with methanol or Thus, green hydrogen produced through green power

ethanol. Such co-production allows low-carbon can be directly added to the syngas in order to fulfill the

hydrogen to be placed on the market at a lower price requirements, another way of conditioning, by which all

than green hydrogen from electrolysis, thus stimulating the carbon contained in waste is converted into final

the implementation of the required infrastructure for molecules and the yield of the process is doubled.

hydrogen use. The methanol and ethanol produced by this scheme

Nevertheless, in a long-term scenario, when the power can be applied as precursors for other chemical

grid will most likely be able to rely on a 100% (or nearly) syntheses and then plastics, thus closing the loop (of

Figure 4. Waste to methanol block scheme.

INDUSTRIAL PLANTS - May 2023

71