Page 18 - Industrial Plants

P. 18

confirmed the loads being consistently within the

calculated acceptable limits.

Conclusions

The Dry Gulch Crossing was a critical activity of the

Trans Mountain Expansion Project, and the pipeline

pullback posed a significant challenge for Bonatti/

Kiewit since their involvement in Spread 5B.

Considering the exceptional length and project

available work space, the engineering, planning, and

setting up of the Dry Gulch HDD pullback required

extraordinary effort and multidisciplinary coordination

from late-2021 to mid-2023 to match high safety and

quality standards, minimize environmental impact, and

optimize the execution schedule. In particular, feasibility

studies, detailed design, and construction engineering

was developed from Q4-2021 to Q1-2023, including

different stages of stress analysis, in static and dynamic

conditions, and 3D modelling of the rollers to size the

Figure 5 - Pullback execution equipment required for string management and pipeline

anchoring.

“Meticulous planning and design

allowed the identification of the

most reliable and efficient solution

for the Dry Gulch HDD pullback,

executed safely and smoothly in only

52 hours, with eight cranes and 17

Bonatti SAFE T-Rex sidebooms - a

major accomplishment for TMEP and

Bonatti, due to compliance, execution

and challenging schedule constraints

The engineered pullback required three pipeline

strings (1,100 metres, 380 metres, and 380 metres in

length), to traverse across 900 metres of rollers

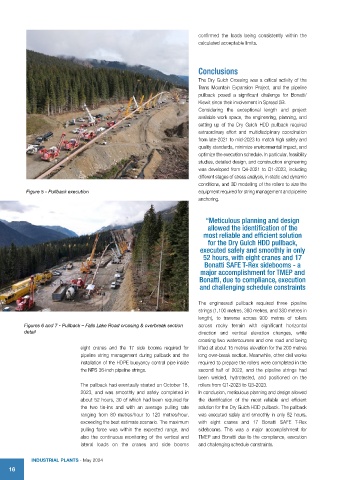

Figures 6 and 7 - Pullback – Falls Lake Road crossing & overbreak section across rocky terrain with significant horizontal

detail direction and vertical elevation changes, while

crossing two watercourses and one road and being

eight cranes and the 17 side booms required for lifted at about 15 metres elevation for the 200 metres

pipeline string management during pullback and the long over-break section. Meanwhile, other civil works

installation of the HDPE buoyancy control pipe inside required to prepare the rollers were completed in the

the NPS 36-inch pipeline strings. second half of 2022, and the pipeline strings had

been welded, hydrotested, and positioned on the

The pullback had eventually started on October 18, rollers from Q1-2023 to Q3-2023.

2023, and was smoothly and safely completed in In conclusion, meticulous planning and design allowed

about 52 hours, 30 of which had been required for the identification of the most reliable and efficient

the two tie-ins and with an average pulling rate solution for the Dry Gulch HDD pullback. The pullback

ranging from 80 metres/hour to 120 metres/hour, was executed safely and smoothly in only 52 hours,

exceeding the best estimate scenario. The maximum with eight cranes and 17 Bonatti SAFE T-Rex

pulling force was within the expected range, and sidebooms. This was a major accomplishment for

also the continuous monitoring of the vertical and TMEP and Bonatti due to the compliance, execution

lateral loads on the cranes and side booms and challenging schedule constraints.

IndustrIal Plants - May 2024

16