Page 50 - Impiantistica Industriale - Settembre Ottobre 2014

P. 50

sel, ammonia etc.), the majority of

transformation technologies cur-

rently deployed (excluding power

generation) require the creation

of synthesis gas (syngas). Syngas

consists primarily of hydrogen and

carbon monoxide in various pro-

portions with some carbon dio-

xide, methane and nitrogen. The

creation of the syngas is typically

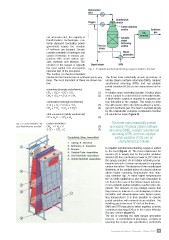

the most capital cost and energy Fig. 4 - In catalytic autothermal reforming oxygen is added to the feed

intensive part of the processes.

The number of chemical reactions

involved in the manufacture of synthesis gas is very The three main industrially proven processes of

large. The most important of these are shown be- tubular steam methane reforming (SMR), catalytic

low. autothermal reforming (ATR), and non-catalytic

partial oxidation (POX) can be characterized as fol-

reforming (strongly endothermic) lows.

CCHH44 + HC2OO2 ↔ CO + 3 2H2H 2 ((21)) In tubular steam reforming reaction (1) takes place

+ ↔ 2 CO + over a catalyst in a tube which is externally heated.

A large steam surplus is required to suppress car-

combustion (strongly exothermic) bon formation in the catalyst. This tends to drive

2CHC4H+4 + OO22 → C2 OC2O++24HH2O2 ((34)) the shift reaction (5) to the right resulting in a hydro-

2 → gen rich synthesis gas. The heat is supplied largely

by the undesirable complete combustion reaction

shift conversion (mildly exothermic) (4) outside the tubes (figure 3).

CO + H2O ↔ CO2 + H2 (5)

Fig. 3 – Foster Wheeler “Ter- carbon formation The three main industrially proven

race Wall reformer module” C2 HC4O→→2CHO2 2++CC (6) processes of tubular steam methane

(7) reforming (SMR), catalytic autothermal

reforming (ATR), and non-catalytic

partial oxidation (POX) can be

characterized as follows

In catalytic autothermal reforming oxygen is added

to the feed (figure 4). The heat requirement for

reaction (1) is largely met by the partial oxidation

reaction (3) pthroudsupcrto. dAusciinngtuabulolawrerrefHo2r/mCinOgrcaotionsiin-

the syngas

derable amounts of steam are required to suppress

carbon formation. The absence of the metallurgical

limitations of the catalyst tubes of a steam reformer

allows higher operating temperatures thus redu-

cing methane slip. At these higher temperatures

the CO shift equilibrium is also more favourable to

CO than in the case of the tubular steam reformer.

In non-catalytic partial oxidation, reaction (3) is do-

minant. The absence of any catalyst means that

the process is tolerant of a small degree of carbon

formation and allows/requires even higher opera-

ting temperatures. It is thus possible to operate

partial oxidation with minimal steam addition. The

resulting gas is the most CO rich of the three.

SMR and ATR may also be taken together, as in the

combined reforming (CR) or in the Foster Wheeler

Banquy scheme (figure 5).

The art of selecting the right syngas generation

process - or combination of processes - consists of

ensuring the correct gas specification, particularly

Impiantistica Italiana - Settembre - Ottobre 2014 49

transformation technologies cur-

rently deployed (excluding power

generation) require the creation

of synthesis gas (syngas). Syngas

consists primarily of hydrogen and

carbon monoxide in various pro-

portions with some carbon dio-

xide, methane and nitrogen. The

creation of the syngas is typically

the most capital cost and energy Fig. 4 - In catalytic autothermal reforming oxygen is added to the feed

intensive part of the processes.

The number of chemical reactions

involved in the manufacture of synthesis gas is very The three main industrially proven processes of

large. The most important of these are shown be- tubular steam methane reforming (SMR), catalytic

low. autothermal reforming (ATR), and non-catalytic

partial oxidation (POX) can be characterized as fol-

reforming (strongly endothermic) lows.

CCHH44 + HC2OO2 ↔ CO + 3 2H2H 2 ((21)) In tubular steam reforming reaction (1) takes place

+ ↔ 2 CO + over a catalyst in a tube which is externally heated.

A large steam surplus is required to suppress car-

combustion (strongly exothermic) bon formation in the catalyst. This tends to drive

2CHC4H+4 + OO22 → C2 OC2O++24HH2O2 ((34)) the shift reaction (5) to the right resulting in a hydro-

2 → gen rich synthesis gas. The heat is supplied largely

by the undesirable complete combustion reaction

shift conversion (mildly exothermic) (4) outside the tubes (figure 3).

CO + H2O ↔ CO2 + H2 (5)

Fig. 3 – Foster Wheeler “Ter- carbon formation The three main industrially proven

race Wall reformer module” C2 HC4O→→2CHO2 2++CC (6) processes of tubular steam methane

(7) reforming (SMR), catalytic autothermal

reforming (ATR), and non-catalytic

partial oxidation (POX) can be

characterized as follows

In catalytic autothermal reforming oxygen is added

to the feed (figure 4). The heat requirement for

reaction (1) is largely met by the partial oxidation

reaction (3) pthroudsupcrto. dAusciinngtuabulolawrerrefHo2r/mCinOgrcaotionsiin-

the syngas

derable amounts of steam are required to suppress

carbon formation. The absence of the metallurgical

limitations of the catalyst tubes of a steam reformer

allows higher operating temperatures thus redu-

cing methane slip. At these higher temperatures

the CO shift equilibrium is also more favourable to

CO than in the case of the tubular steam reformer.

In non-catalytic partial oxidation, reaction (3) is do-

minant. The absence of any catalyst means that

the process is tolerant of a small degree of carbon

formation and allows/requires even higher opera-

ting temperatures. It is thus possible to operate

partial oxidation with minimal steam addition. The

resulting gas is the most CO rich of the three.

SMR and ATR may also be taken together, as in the

combined reforming (CR) or in the Foster Wheeler

Banquy scheme (figure 5).

The art of selecting the right syngas generation

process - or combination of processes - consists of

ensuring the correct gas specification, particularly

Impiantistica Italiana - Settembre - Ottobre 2014 49