Page 91 - impiantistica_3_2015

P. 91

R AM (Reliability, Availability & LNG industry history and

Maintainability) analysis is a context

modeling technique that has its

origin in the military sector involving From the 19th century to nowadays, the LNG

the V-1 missile team during World

War II (MIL-HDBK-338B, 1998 [1]). (Liquefied Natural Gas) industry has greatly

It was here that it became first understood that evolved. The first LNG plant was built in West

an improvement in the reliability of individual Virginia in 1912 and began operation in 1917.

components and reconfiguring the system Then, the first commercial liquefaction plant was

to improve reliability resulted in an increased built in Cleveland, Ohio, in 1941. In January 1959,

likelihood of success. Reliability was then quickly the world’s first LNG tanker, The Methane Pioneer,

adopted in industries a converted World

where understanding FLNG (Floating Liquefied Natural Gas) War II liberty freighter

of and improvements in are now arising as a reality and with containing five 7,000

the reliability of complex Capital Expenditure (Capex) that can barrel equivalent tanks

systems were required, reach about $12 billion, it is easily showed to the world a

namely by the National new way to extend the

Aeronautics and Space understandable that production LNG transportation.

Administration (NASA) availability but also maintainability and Nowadays, LNG storage

and the nuclear power reliability are seen as a critical aspect tanks of about 160,000

industry to prevent for organisations’ project economics by m3 are in use and much

such accidents as larger LNG ships are

experienced at a all the operating companies. expected to come in

nuclear power plant at the next few years.

Three Mile Island (USA, Thus, the conventional

March 28, 1979) and LNG industry could be

the explosion of the space shuttle Challenger summarized by figure 1.

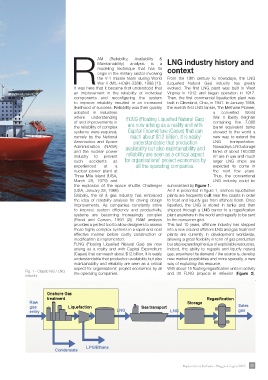

(USA, January 28, 1986). As it is presented in figure 1, onshore liquefaction

Globally, the oil & gas industry has embraced plants are frequently built near the coasts in order

the idea of reliability analysis for driving design to treat and liquefy gas from offshore fields. Once

improvements. As companies constantly strive liquefied, the LNG is stored in tanks and then

to improve system efficiency and productivity, shipped through a LNG carrier to a regasification

systems are becoming increasingly complex plant anywhere in the world and regasify to be sent

(Flood and Carson, 1993 [2]). RAM analysis to the consumer grid.

provides a perfect tool to allow designers to assess This last 10 years, offshore industry has stepped

these highly complex systems in a rapid and cost into a new era and offshore LNG and gas treatment

effective manner before costly construction or plants are currently in development worldwide,

modification is implemented. allowing a great flexibility in term of gas production

FLNG (Floating Liquefied Natural Gas) are now but also expanding the size of exploitable resources.

arising as a reality and with Capital Expenditure Indeed, the ability to regasify and liquefy natural

(Capex) that can reach about $12 billion, it is easily gas, anywhere the demand / the source is, develop

understandable that production availability but also new market possibilities and more specially, a new

maintainability and reliability are seen as a critical way of exploiting this resource.

Fig. 1 - Classic NG / LNG aspect for organisations’ project economics by all With about 15 floating regasification units in activity

industry

the operating companies. and 30 FLNG projects in reflexion (figure 2),

Impiantistica Italiana - Maggio-Giugno 2015 89