Page 63 - Impiantistica industriale

P. 63

Figure 5: The danger of eva-

porating condensate

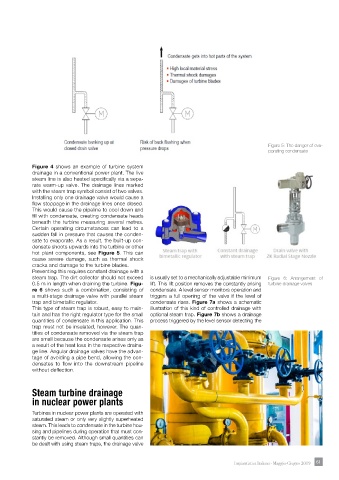

Figure 4 shows an example of turbine system

drainage in a conventional power plant. The live

steam line is also heated specifically via a sepa-

rate warm-up valve. The drainage lines marked

with the steam trap symbol consist of two valves.

Installing only one drainage valve would cause a

flow stoppage in the drainage lines once closed.

This would cause the pipeline to cool down and

fill with condensate, creating condensate heads

beneath the turbine measuring several metres.

Certain operating circumstances can lead to a

sudden fall in pressure that causes the conden-

sate to evaporate. As a result, the built-up con-

densate shoots upwards into the turbine or other

hot plant components, see Figure 5. This can

cause severe damage, such as thermal shock

cracks and damage to the turbine blades.

Preventing this requires constant drainage with a

steam trap. The dirt collector should not exceed is usually set to a mechanically adjustable minimum Figure 6: Arrangement of

0.5 m in length when draining the turbine. Figu- lift. This lift position removes the constantly arising turbine drainage valves

re 6 shows such a combination, consisting of condensate. A level sensor monitors operation and

a multi-stage drainage valve with parallel steam triggers a full opening of the valve if the level of

trap and bimetallic regulator. condensate rises. Figure 7a shows a schematic

This type of steam trap is robust, easy to main- illustration of this kind of controlled drainage with

tain and has the right regulator type for the small optional steam trap. Figure 7b shows a drainage

quantities of condensate in this application. This process triggered by the level sensor detecting the

trap must not be insulated, however. The quan-

tities of condensate removed via the steam trap

are small because the condensate arises only as

a result of the heat loss in the respective draina-

ge line. Angular drainage valves have the advan-

tage of avoiding a pipe bend, allowing the con-

densates to flow into the downstream pipeline

without deflection.

Steam turbine drainage

in nuclear power plants

Turbines in nuclear power plants are operated with

saturated steam or only very slightly superheated

steam. This leads to condensate in the turbine hou-

sing and pipelines during operation that must con-

stantly be removed. Although small quantities can

be dealt with using steam traps, the drainage valve

Impiantistica Italiana - Maggio-Giugno 2019 61 61