Page 64 - Impiantistica industriale

P. 64

componenTs

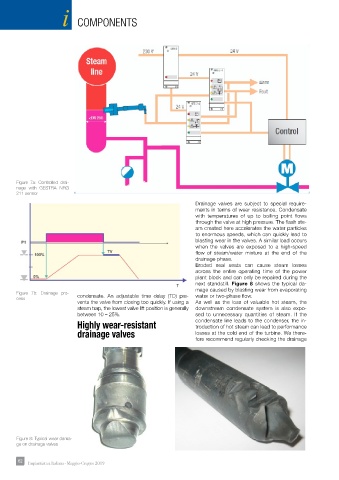

Figure 7a: Controlled drai-

nage with GESTRA NRG

211 sensor

Drainage valves are subject to special require-

ments in terms of wear resistance. Condensate

with temperatures of up to boiling point flows

through the valve at high pressure. The flash ste-

am created here accelerates the water particles

to enormous speeds, which can quickly lead to

blasting wear in the valves. A similar load occurs

when the valves are exposed to a high-speed

flow of steam/water mixture at the end of the

drainage phase.

Eroded seal seats can cause steam losses

across the entire operating time of the power

plant block and can only be repaired during the

next standstill. Figure 8 shows the typical da-

mage caused by blasting wear from evaporating

Figure 7b: Drainage pro- condensate. An adjustable time delay (TD) pre- water or two-phase flow.

cess

vents the valve from closing too quickly. If using a As well as the loss of valuable hot steam, the

steam trap, the lowest valve lift position is generally downstream condensate system is also expo-

between 10 – 25%. sed to unnecessary quantities of steam. If the

Highly wear-resistant condensate line leads to the condenser, the in-

troduction of hot steam can lead to performance

drainage valves losses at the cold end of the turbine. We there-

fore recommend regularly checking the drainage

Figure 8: Typical wear dama-

ge on drainage valves

62 62 Impiantistica Italiana - Maggio-Giugno 2019