Page 62 - Impiantistica industriale

P. 62

componenTs

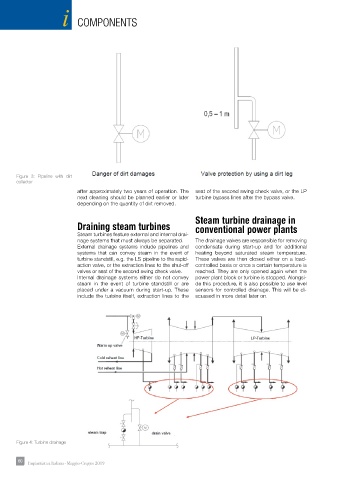

Figure 3: Pipeline with dirt

collector

after approximately two years of operation. The seat of the second swing check valve, or the LP

next cleaning should be planned earlier or later turbine bypass lines after the bypass valve.

depending on the quantity of dirt removed.

Steam turbine drainage in

Draining steam turbines conventional power plants

Steam turbines feature external and internal drai-

nage systems that must always be separated. The drainage valves are responsible for removing

External drainage systems include pipelines and condensate during start-up and for additional

systems that can convey steam in the event of heating beyond saturated steam temperature.

turbine standstill, e.g. the LS pipeline to the rapid- These valves are then closed either on a load-

action valve, or the extraction lines to the shut-off controlled basis or once a certain temperature is

valves or seat of the second swing check valve. reached. They are only opened again when the

Internal drainage systems either do not convey power plant block or turbine is stopped. Alongsi-

steam in the event of turbine standstill or are de this procedure, it is also possible to use level

placed under a vacuum during start-up. These sensors for controlled drainage. This will be di-

include the turbine itself, extraction lines to the scussed in more detail later on.

Figure 4: Turbine drainage

60 60 Impiantistica Italiana - Maggio-Giugno 2019