Page 65 - Impiantistica industriale

P. 65

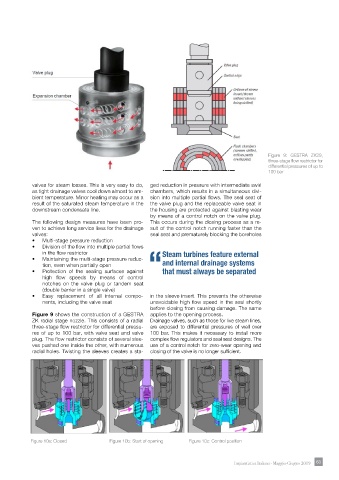

Figure 9: GESTRA ZK29,

three-stage flow restrictor for

differential pressures of up to

100 bar

valves for steam losses. This is very easy to do, ged reduction in pressure with intermediate swirl

as tight drainage valves cool down almost to am- chambers, which results in a simultaneous divi-

bient temperature. Minor heating may occur as a sion into multiple partial flows. The seal seat of

result of the saturated steam temperature in the the valve plug and the replaceable valve seat in

downstream condensate line. the housing are protected against blasting wear

by means of a control notch on the valve plug.

The following design measures have been pro- This occurs during the closing process as a re-

ven to achieve long service lives for the drainage sult of the control notch running faster than the

valves: seal seat and prematurely blocking the boreholes

• Multi-stage pressure reduction

• Division of the flow into multiple partial flows

in the flow restrictor Steam turbines feature external

• Maintaining the multi-stage pressure reduc-

tion, even when partially open and internal drainage systems

• Protection of the sealing surfaces against “that must always be separated

high flow speeds by means of control

notches on the valve plug or tandem seat

(double barrier in a single valve)

• Easy replacement of all internal compo- in the sleeve insert. This prevents the otherwise

nents, including the valve seat unavoidable high flow speed in the seal shortly

before closing from causing damage. The same

Figure 9 shows the construction of a GESTRA applies to the opening process.

ZK radial stage nozzle. This consists of a radial Drainage valves, such as those for live steam lines,

three-stage flow restrictor for differential pressu- are exposed to differential pressures of well over

res of up to 100 bar, with valve seat and valve 100 bar. This makes it necessary to install more

plug. The flow restrictor consists of several slee- complex flow regulators and seal seat designs. The

ves pushed one inside the other, with numerous use of a control notch for zero-wear opening and

radial holes. Twisting the sleeves creates a sta- closing of the valve is no longer sufficient.

Figure 10a: Closed Figure 10b: Start of opening Figure 10c: Control position

Impiantistica Italiana - Maggio-Giugno 2019 63 63