Page 97 - impiantistica_3_2015

P. 97

Information gathering & project • probability of achieving given production rates

familiarization over time;

The RAM process begins with a thorough review of • probability distributions for both overall (system

equipment lists, PFDs, P&IDs, process descriptions life) and annual production availabilities;

and operation manuals. Understanding should

be established to ensure modeling will reflect • production loss contribution breakdown by

maintenance and operations as realistically and system & individual equipment items;

accurately as possible. It is important at this stage

to clearly define what is expected from the RAM • contribution to production loss from

modeling which may simply include the identification operational behaviours such as restart delays;

of equipment critical to production assurance or the

prediction of production availability and production • maintenance intervention frequencies;

throughput. • frequency and duration of shutdowns with

In our case, objectives have been clearly defined

by the client and results to be reported were as breakdown of contributors.

follows:

• average production availability over system life Reliability data

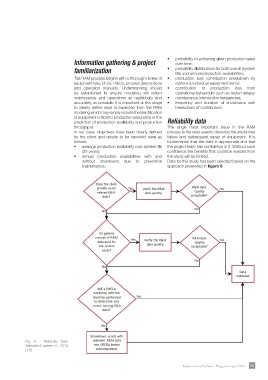

(25 years); The single most important issue in the RAM

• annual production availabilities with and process is the data used to describe the unplanned

failure and subsequent repair of equipment. It is

without shutdowns due to preventive fundamental that the data is appropriate and that

maintenance; the project team has confidence in it. Without such

confidence the benefits that could be realized from

the study will be limited.

Data for this study has been selected based on the

approach presented in figure 6.

Fig. 6 - Reliability Data

Selection (Lawrenz H., 2014

[11])

Impiantistica Italiana - Maggio-Giugno 2015 95