Page 98 - impiantistica_3_2015

P. 98

Table 2 - Clean service It has to be noted that as FLNG projects are new reduced amount of elements/particles are capable

failure rate technologies, no operational data was available to degrade the materials and equipment items that

among company or contractor experience. General compose the system. Thus, failure data for such

selection principle of reliability data has been based “clean service” can be adapted. Table 2: presents

on Norsok Z-016 [12] qualification method. the failure modes which have been removed

As most of the data for this project was issued from (partially and totally) and final contribution to be

Oreda 09 [13], a particular attention was given to removed from the failure rate in order to improve

the equipment boundaries in order to avoid any reliability data in a realistic manner.

over/under estimation of the reliability data effect Exponential distribution has been used to represent

on a subsystem. the failure repair duration.

Failure rate from Oreda 09 was extracted from the

“Failure rate – Mean” column meaning that Oreda RAM assumptions

estimator have been applied. Failure rate obtained

by the Oreda estimator represents the mean failure RAM model describes equipment in terms of

rate among the installation for which data have their capacity, redundancy, and failure effect. The

been collected. The model has systematically capacities, redundancies and failure effects used

incorporated exponential distributions to represent in a specific RAM model are collectively referred

the failure rate of equipment. The exponential to as the model assumptions. To describe RAM

distribution, which is not time dependent, is the models, an assumptions document commonly

most commonly used distribution as it is the best consists of Reliability Block Diagrams, an Asset

representation of a random failure. Probability of Register as well as the list of critical equipment of

failure on demand as well as early life failure related each system as defined in the section “criticality”. In

to post commissioning has not been considered order to ensure a good quality assurance process,

in the analysis. Only critical (CRT) failure modes equipment not critical for the production have been

have been modeled in the base case but degraded listed as well in order to ensure all the elements of

failure modes has been explored into a sensitivity the system have been reviewed by the RAM team

case. and proper justification of their exclusion has been

Failure rate values have been modified when made.

necessary to take into account specificities of Failure modes, MTTF, MTTR, Preparation times

the different equipment items, process conditions including permitting process as well as other

and operational conditions of the installation. For mobilisation times (crew, specialists, MSV, ISV,

instance, one typical case where the reliability Modu interventions), sparing lead time and

data has to be adapted with FLNG process is preparation time have been taken into account

when system is exposed only to clean gas. When by type of equipment and summarized into the

a system deals with clean gas or LNG, only a Asset Register. An example of the Asset Register

developed for the study is presented in table 3.

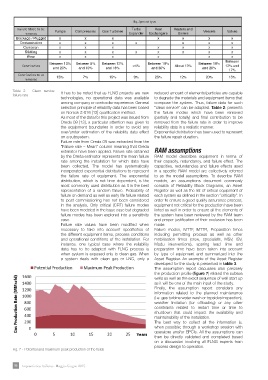

Fig. 7 - Potential and maximum peak production of the fields The assumption report discusses also precisely

the production profile (figure 7) related the subsea

wells as well as the exact sequence of well start up

as it will be one of the main input of the study.

Finally, the assumption report considers any

information related to the planned maintenance

(i.e. gas turbine water wash or topsides inspection),

weather limitation (for offloading) or any other

constraints related to restart time or time to

shutdown that could impact the availability and

maintainability of the installation.

The best way to collect all the information is,

when possible; through a workshop session with

operators and/or EPCIs. All the assumptions can

then be directly validated and completed based

on a discussion involving all FLNG experts from

process design to operation.

96 Impiantistica Italiana - Maggio-Giugno 2015