Page 99 - impiantistica_3_2015

P. 99

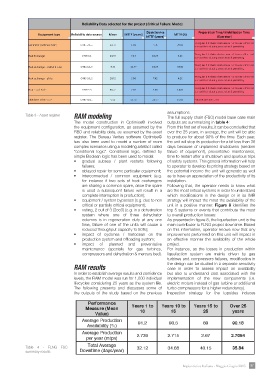

Table 3 - Asset register RAM modeling assumptions.

The full supply chain (FSC) model base case main

The model construction in Optimise© involved outputs are summarizing in table 4:

the equipment configuration, as assumed by the From this first set of results, it can be concluded that

RBD and reliability data, as assumed by the asset over the 25 years, in average, the unit will be able

register. The Bureau Veritas software Optimise© to produce for about 90% of the time. Each year,

has also been used to model a number of more the unit will stop its production for a bit less than 36

complex scenarios using a modeling artefact called days because of unplanned shutdowns (random

“conditional logic”. Conditional logic, defined by failure of equipment), preventative maintenance,

simple Boolean logic has been used to model: time to restart after a shutdown and spurious trips

• gradual subsea / plant restarts following of safety systems. This general information will help

to operator to develop its pricing strategy based on

failures; the potential income the unit will generate as well

• delayed repair for some particular equipment; as to have an appreciation of the productivity of its

• interconnected / common equipment (e.g. installation.

Following that, the operator needs to know what

for instance if two sets of heat exchangers are the most critical systems in order to understand

are sharing a common spare, once the spare which modifications in the design or in its IMR

is used a subsequent failure will result in a strategy will impact the most the availability of the

complete interruption in production); unit in a positive manner. Figure 8 identifies the

• equipment / system bypasses (e.g. due to non top 5 systems or events that contribute the most

critical or partially critical equipment); to overall production losses:

• voting, 2 out of 3 (2oo3) (e.g. in a dehydration As presented in figure 8, the liquefaction unit is the

system where one of three dehydrator main contributor to FLNG project downtime. Based

columns is in regeneration duty at any one on this information, operator knows now that any

time, failure of one of the units will cause a improvement performed on this unit will impact in

reduced throughput capacity to 50%); an effective manner the availability of the whole

• impact of cyclones / metocean on the project.

production system and offloading system; For instance, as the losses in production within

• impact of planned and preventative liquefaction system are mainly driven by gas

maintenance (specially for gas turbines, turbines and compressors failures, modification in

compressors and dehydration & mercury bed). the design can be studied in a separate sensitivity

case in order to assess impact on availability

RAM results but also to understand cost associated with the

implementation of the new components (i.e.

In order to establish average results and confidence electric motors instead of gas turbine or additional

levels, the RAM model was run for 1,000 individual turbo compressors for a higher redundancy).

lifecycles considering 25 years as the system life. Inspection strategy for the topsides induces

The following presents and discusses some of

the outputs of the study based on the previous

Table 4 - FLNG FSC

summary results

Impiantistica Italiana - Maggio-Giugno 2015 97