Page 51 - Impiantistica Novembre-Dicemvre 2015

P. 51

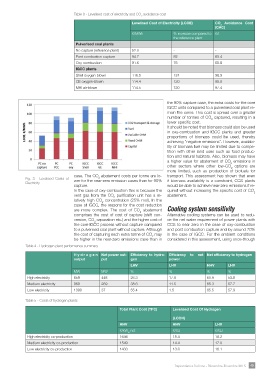

Table 3 - Levelised cost of electricity and CO2 avoidance cost

Levelised Cost of Electricity (LCOE) C(COA2C)Avoidance Cost

€/t

€/MWh % increase compared to

the reference plant

Pulverised coal plants 52.0 - -

No capture (reference plant) 94.7 82 65.4

Post combustion capture 91.6 76 60.8

Oxy-combustion

IGCC plants 116.5 124 98.9

Shell oxygen-blown 114.4 120 95.8

GE oxygen-blown 114.5 120 97.4

MHI air-blown

the 90% capture case, the extra costs for the core

IGCC units compared to a pulverised coal plant re-

main the same. This cost is spread over a greater

number of tonnes of CO2 captured, resulting in a

lower specific cost.

It should be noted that biomass could also be used

in oxy-combustion and IGCC plants and greater

proportions of biomass could be used, thereby

achieving “negative emissions”. However, availabi-

lity of biomass fuel may be limited due to compe-

tition with other land uses such as food produc-

tion and natural habitats. Also, biomass may have

a higher value swfuohcr eharbeaastoetpmhreoerdnutlocowtfio-CCnOOo22f emissions in

other sectors options are

more limited, biofuels for

Fig. 3 - Levelised Costs of wcaesref.oTr htheeCnOea2 ra-zbeartoememenistscioonstcsaspeesr tonne are lo- transport. This assessment has shown that even

Electricity than for 90%

if biomass availability is a constraint, CCS plants

capture. would be able to achieve near-zero emissions if re-

In the case of oxy-combustion this is because the quired without increasing the specific cost of CO2

abatement.

lcvaeatnisvetelgyoafhsIiGgfrhCoCmC,Otth2heecoCrenOacse2onpntursaritffiioocrnatti(ho2en5%cuonsmitt ohrela).dsuInacttirohene-

Cooling system sensitivity

are more complex. The cost ocfapCtOur2e abatement

comprises the cost of cost of (shift con- Alternative cooling systems can be used to redu-

ce the net water requirement of power plants with

tvheerscioonre, CIGOC2 Cseppraorcaetiossn etc.) and the higher cost of CCS to near zero in the case of oxy-combustion

without capture compared and post combustion capture and by around 70%

in the case of IGCC. For the ambient conditions

to a pulverised coal plant without capture. Although considered in this assessment, using once-though

the cost of capturing each eexmtriasstioonnnsecoafsCe Oth2amn ainy

be higher in the near-zero

Table 4 - Hydrogen plant performance summary

H y d r o g e n Net power out- Efficiency to hydro- Efficiency to net Net efficiency to hydrogen

output put gen power

LHV LHV HHV LHV

MW MW % % %%

High electricity 659 448 26.3 17.8 60.9 53.8

Medium electricity

Low electricity 969 289 38.6 11.5 65.3 57.7

1390 37 55.4 1.5 65.5 57.9

Table 5 - Costs of hydrogen plants Total Plant Cost (TPC) Levelised Cost Of Hydrogen

High electricity co-production HHV (LCOH) LHV

Medium electricity co-production €/kWH net HHV €/GJ

Low electricity co-production 1646 €/GJ 18.2

1549 15.4 17.0

1430 14.4 16.1

13.6

Impiantistica Italiana - Novembre-Dicembre 2015 49