Page 22 - Impiantistica Industriale

P. 22

Stage 6 – Module execution

phase

During this stage of the project, detailed enginee-

ring was carried out to finalise module design and

build.

The Project Execution Plan for the module execu-

tion phase considered the following issues:

Engineering

• Accelerated engineering activities compared

with a conventional approach. In particular,

structural design required a greater effort at

the commencement of this phase;

• Foundation and underground design should

incorporate module, crane and transportation

requirements;

• Documents and drawings shall be produced

on a module-by-module basis, in alignment

with the needs of the construction schedule,

and must address the detailed module design

requirements, such as cable routing, hook-up

access, etc. Each module was set up as one

or more separate construction area(s) in the

project to facilitate this.

• Weight management and centre-of-gravity con-

trol throughout the module execution phase;

• Module envelope management;

• Multiple critical paths and sequences within

the schedule.

Procurement

• Accelerated procurement activities compared

with the conventional approach;

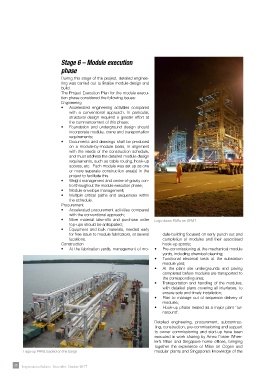

• More material take-offs and purchase order Legs-down PARs on SPMT

top-ups should be anticipated;

• Equipment and bulk materials, needed early

for free issue to module fabricators, at several dule-building focused on early punch out and

locations. completion of modules and their associated

Construction hook-up spools;

• At the fabrication yards, management of mo- • Pre-commissioning at the mechanical module

yards, including chemical cleaning;

• Functional electrical tests at the substation

module yard;

• At the plant site undergrounds and paving

completed before modules are transported to

the corresponding area;

• Transportation and handling of the modules,

with detailed plans covering all interfaces, to

ensure safe and timely installation;

• Plan to manage out of sequence delivery of

modules;

• Hook-up phase treated as a major plant ‘tur-

naround’.

Detailed engineering, procurement, subcontrac-

ting, construction, pre-commissioning and support

to owner commissioning and start-up have been

executed in work sharing by Amec Foster Whee-

ler’s Milan and Singapore home offices, bringing

together the experience of Milan on Cogen and

Legs-up PARs loaded on the barge modular plants and Singapore’s knowledge of the

20 Impiantistica Italiana - Settembre-Ottobre 2017