Page 30 - 62

P. 30

Engineering phase high-risk schedule, as there is also no possibility to

Since the bid phase, long before the certainty of perform other parallel activities on a convection

performing the job, Vergaengineering trooped a section (such as steelwork welding, supports

dedicated design task force with the mission of modification or refractory works) while the coil is in

seeking the best technical solutions for minimizing course of replacement.

realization risks, time and costs. Moreover, the 20 m tubes, even if of big diameter,

The tough requirements were faced through many are very flexible and generally lead to high

solutions, among which modularization had the leading installation time, which had to be added to the

role to bring decisive turning point in success. time required for all the site welds needed, with

Below the 3 parallel projects are described in details. consequent post weld heat treatment, hardness

I) The radiant sections revamping required many check, x-rays, magnetic and hydrostatic tests.

activities, but the big challenge was to completely In order to solve the matter, Vergaengineering

replace the connected six-passes coils in less- used a specifically designed device to save time

than-one-month turnaround. Difficulty-level was for such kind of jobs: a bundle puller, which

additionally increased, as the coils diameter had to allowed a quicker-than-usual installation of the coil

change, with the consequent variation of one hairpin at the time.

mechanical interfaces between the coils and the III) The highest-impact part of the project, with

structures. reference to weight and dimensions, was the

An uncommon solution solved the puzzle: since entire replacement of the visbreaker unit pre-

the coils in the vertical heaters were supported in heating system: an old ~250 tons structure to be

the top part of the radiant sections, the quickest demolished and a new ~250 tons structure (with

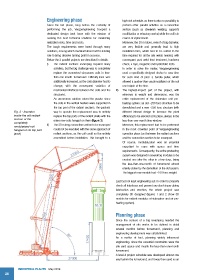

Fig. 3 - Insertion way to operate the replacement was to entirely different internal design to increase the plant

inside the old radiant replace the top parts of the radiant shells with the efficiency) to be erected at its place, always in the

section of the entire new coils hanged on them (figure 3). less-than-one-month time window.

completely II) The 20 m long convection section to be revamped

modularized coil Moreover, this replacement had to be performed

hanged on its top part could not be executed with the same approach of in the most crowded point of Vergaengineering

(arch) radiant sections, as the coil could not be entirely operation place: just between the radiant sections

assembled before installation. This brought to a and the convection section to be revamped.

Of course, modularization was an essential

expedient to cope with space and time

requirements. Consequently, the entire preheating

system was designed in several big modules to be

erected one after the other in a few days, being

the less-than-one-month of turnaround almost

entirely stolen by the demolition of the old system.

The biggest new module had ~100 tons weight.

Last but not least engineering act: in order to properly

check all interfaces and prevent any clash issue during

fabrication and erection, the whole project was

completely 3D designed (figures 1 and 2 show 3D

models for radiant modules of visbreaker and air pre-

heating system).

Planning phase

Since the context of a big revamping needed the

management of site works to be defined in detail

several months before turnaround, planning and

engineering development was strictly linked.

As a matter of fact, planning widely influenced

engineering, since the essential constraints were the

site yard space and mostly the less-than-one-month

turnaround.

A level-4 project schedule was developed almost one

year before the turnaround, and it was then used as an

IndustrIal Plants - May 2018

26