Page 29 - Impiantistica Italiana

P. 29

Wheeler signed a cooperation agree- The VESTA technology has great flexi-

ment with Clariant International, the ca- bility in terms of gas quality at the inlet Bio-SNG Production

talyst supplier, and Wison Engineering to battery limit. Indeed, the methanation Schemes

build a pilot plant in China demonstra- process developed of Wood can handle

ting the VESTA Substitute Natural Gas syngas of a wide variety of composi- The three production schemes for Bio-

(SNG) technology. The pilot plant has tions, coming from different sources SNG production involve the following sy-

been erected in Nanjing for a production such as the biomass gasification, biogas stems, which represent the bricks upstre-

3

capacity of 100 Nm /h of SNG and con- upgrading, and Power to Gas applica- am the methanation process and relevant

ducted two successful test campaigns tion described in the following section, syngas conditioning:

in 2014 and 2015/2016 to demonstrate and can adapt to different purification • Biomass gasification

a continuous operation at 100% SNG methodologies. • Biogas upgrading

production meeting the Chinese natural • Power to Gas application

gas grid specification, and to test diffe-

rent operating parameters including all

the reactors and control system.

The plant operation, as well as the catalyst

performance, has been perfectly in line

with the expected data.

VESTA process can produce up to

250,000 Nm /h of SNG in a single train

3

without recycle compressor and without

risk of temperature runaway or metal

dusting. The highest temperature in

the VESTA process does not overcome

550°C: internal lining reactors are not

required. All these features make the

VESTA process a very attractive option

for the market and Wood is ready for its

commercialization.

Moreover, in the renewable field the com-

mercial feasibility of the Bio-SNG proces-

ses will be established in the next few Fig. 3a

months by means of a Biomass-to-SNG

demonstration plant as part of a pro-

gramme to develop and commercialise

technologies required to decarbonise the

transport sector, which was funded by

the UK’s Department for Transport and

by National Grid Gas Distribution. Now

that the necessary technical research

has been completed and consolidated,

this project focuses on the commercial

innovation necessary to enable the con-

struction of commercial plants. Funders,

waste suppliers, power off-takers and Fig.3b

construction contractors are generally

unwilling to accept the risks associated

with a first of a kind plant and require a

demonstration that the technology can

be operated commercially before develo-

ping large scale facilities. Indeed, that 4.5

MWth demonstration plant will produce

enough compressed SNG to power 75

heavy goods vehicles. The Biomass-to-

SNG Demonstration scope consists of a

Basic Engineering Design (BED) followed

by Engineering Procurement & Fabri-

cation (EPF) of VESTA SNG technology

which includes the following sections:

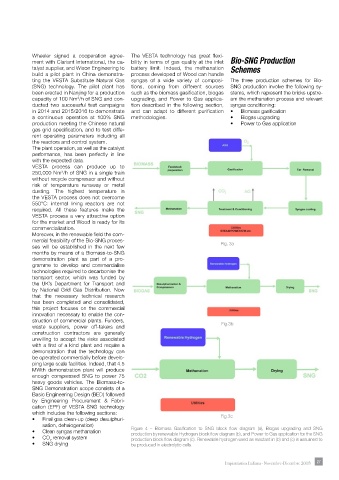

• Final gas clean-up (deep desulphuri- Fig.3c

sation, dehalogenation)

• Clean syngas methanation Figure 4 – Biomass Gasification to SNG block flow diagram (a), Biogas upgrading and SNG

production by renewable Hydrogen block flow diagram (b), and Power to Gas application for the SNG

• CO removal system production block flow diagram (c). Renewable hydrogen used as reactant in (b) and (c) is assumed to

2

• SNG drying be produced in electrolytic cells.

Impiantistica Italiana - Novembre-Dicembre 2018 27