Page 55 - 83

P. 55

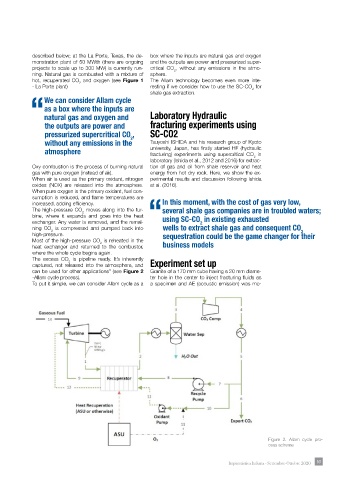

described below; at the La Porte, Texas, the de- box where the inputs are natural gas and oxygen

monstration plant of 50 MWth (there are ongoing and the outputs are power and pressurized super-

projects to scale up to 300 MW) is currently run- critical CO , without any emissions in the atmo-

2

ning. Natural gas is combusted with a mixture of sphere.

hot, recuperated CO and oxygen (see Figure 1 The Allam technology becomes even more inte-

2

- La Porte plant) resting if we consider how to use the SC-CO for

2

shale gas extraction.

We can consider Allam cycle

as a box where the inputs are

“natural gas and oxygen and Laboratory Hydraulic

the outputs are power and fracturing experiments using

pressurized supercritical CO , SC-CO2

2

without any emissions in the Tsuyoshi ISHIDA and his research group of Kyoto

atmosphere university, Japan, has firstly started HF (hydraulic

fracturing) experiments using supercritical CO in

2

laboratory (Ishida et al., 2012 and 2016) for extrac-

Oxy combustion is the process of burning natural tion of gas and oil from shale reservoir and heat

gas with pure oxygen (instead of air). energy from hot dry rock. Here, we show the ex-

When air is used as the primary oxidant, nitrogen perimental results and discussion following Ishida

oxides (NOX) are released into the atmosphere. et al. (2016).

When pure oxygen is the primary oxidant, fuel con-

sumption is reduced, and flame temperatures are

increased, adding efficiency. In this moment, with the cost of gas very low,

The high-pressure CO moves along into the tur- several shale gas companies are in troubled waters;

2

bine, where it expands and goes into the heat “using SC-CO in existing exhausted

exchanger. Any water is removed, and the remai- 2

ning CO is compressed and pumped back into wells to extract shale gas and consequent CO

2

2

high-pressure. sequestration could be the game changer for their

Most of the high-pressure CO is reheated in the

2

heat exchanger and returned to the combustor, business models

where the whole cycle begins again.

The excess CO is pipeline ready. It’s inherently

captured, not released into the atmosphere, and Experiment set up

2

can be used for other applications” (see Figure 2 Granite of a 170 mm cube having a 20 mm diame-

-Allam cycle process). ter hole in the center to inject fracturing fluids as

To put it simple, we can consider Allam cycle as a a specimen and AE (acoustic emission) was mo-

Figure 2. Allam cycle pro-

cess scheme

Impiantistica Italiana - Settembre-Ottobre 2020 53