Page 74 - Impiantistica industriale

P. 74

OPPORTUNITIES

tchem S.p.A. has developed its own CPO technology.

23

The figure 2 draws the attention to the incomparable

compactness of the SCT-CPO over the SMR, while the

figure 3 shows an example of a 300Nm3/h H2 plant

capacity.

Methanol synthesis

Methanol synthesis is performed in catalytic reactors

containing a solid catalyst and can be described with the

following main equilibrium reactions:

CO + 2H ↔ CH OH ΔH° 298 K = -91 kJ/mol [1]

3

2

CO + 3H ↔ CH OH + 2 H O ΔH° 298 K = -49 kJ/mol [2]

2

3

2

2

CO + H O ↔ CO + H ΔH° = -41 kJ/mol [3]

2 2 2 298 K

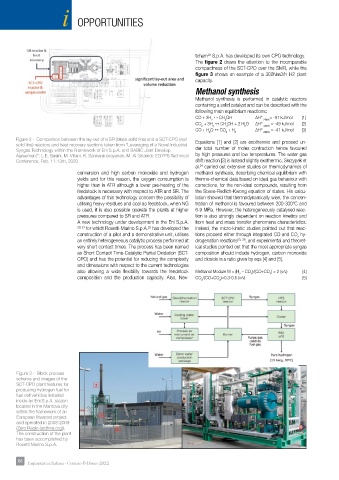

Figure 2 - Comparison between the lay-out of a SR (black solid line) and a SCT-CPO (red Equations [1] and [2] are exothermic and proceed un-

solid line) reactors and heat recovery sections taken from “Leveraging of a Novel Industrial

Syngas Technology within the Framework of Eni S.p.A. and SABIC Joint Develop der total number of moles contraction hence favoured

Agreement”; L.E. Basini, M. Villani, K. Sankaranarayanan, M. Al Ghamdi; EGYPS Technical by high pressures and low temperatures. The water gas

Conference, Feb. 11-13th, 2020 shift reaction [3] is instead slightly exothermic. Skrzypek et

al. carried out extensive studies on thermodynamics of

24

conversion and high carbon monoxide and hydrogen methanol synthesis, describing chemical equilibrium with

yields and for this reason, the oxygen consumption is thermo-chemical data based on ideal gas behaviour with

higher than in ATR although a lower pre-heating of the corrections, for the non-ideal compounds, resulting from

feedstock is necessary with respect to ATR and SR. The the Soave-Redlich-Kwong equation of states. His calcu-

advantages of this technology concern the possibility of lation showed that thermodynamically wise, the concen-

utilising heavy residues and coal as feedstock, when NG tration of methanol is favoured between 200-300°C and

is used, it is also possible operate the plants at higher 6-9 MPa. However, the heterogeneously catalysed reac-

pressures compared to SR and ATR. tion is also strongly dependent on reaction kinetics and

A new technology under development in the Eni S.p.A. from heat and mass transfer phenomena characteristics.

22

20, 21 for which Rosetti-Marino S.p.A. has developed the Indeed, the micro-kinetic studies pointed out that reac-

construction of a pilot and a demonstrative unit, utilises tions proceed either through integrated CO and CO hy-

2

an entirely heterogeneous catalytic process performed at drogenation reactions , and experimental and theoret-

25, 26

very short contact times. The process has been named ical studies pointed out that the most appropriate syngas

as Short Contact Time-Catalytic Partial Oxidation (SCT- composition should include hydrogen, carbon monoxide

CPO) and has the potential for reducing the complexity and dioxide in a ratio given by eqs [4] and [5].

and dimensions with respect to the current technologies

also allowing a wide fl exibility towards the feedstock Methanol Module M = (H – CO )/(CO+CO ) = 2 (v/v) [4]

2

2

2

composition and the production capacity. Also, Nex- CO /(CO+CO )=0.3-0.5 (v/v) [5]

2

2

Figure 3 - Block process

scheme and images of the

SCT-CPO plant features for

producing hydrogen fuel for

fuel cell vehicles installed

inside an Eni S.p.A. station

located in the Mantova city

within the framework of an

European fi nanced project

and operated in 2008-2009

(Zero Regio (archive.org)).

The construction of the plant

has been accomplished by

Rosetti Marino S.p.A.

68 68 Impiantistica Italiana - Gennaio-Febbraio 2022