Page 105 - Impiantistica industriale

P. 105

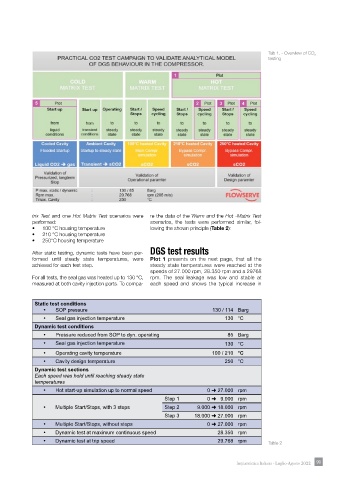

Tab 1. - Overview of CO 2

testing

trix Test and one Hot Matrix Test scenarios were re the data of the Warm and the Hot -Matrix Test

performed: scenarios, the tests were performed similar, fol-

• 100 °C housing temperature lowing the shown principle (Table 2):

• 210 °C housing temperature

• 250°C housing temperature

After static testing, dynamic tests have been per- DGS test results

formed until steady state temperatures, were Plot 1 presents on the next page, that all the

achieved for each test step. steady state temperatures were reached at the

speeds of 27.000 rpm, 28.350 rpm and a 29768

For all tests, the seal gas was heated up to 130 °C, rpm. The seal leakage was low and stable at

measured at both cavity injection ports. To compa- each speed and shows the typical increase in

Static test conditions

• SOP pressure 130 / 114 Barg

• Seal gas injection temperature 130 °C

Dynamic test conditions

• Pressure reduced from SOP to dyn. operating 85 Barg

• Seal gas injection temperature 130 °C

• Operating cavity temperature 100 / 210 °C

• Cavity design temperature 250 °C

Dynamic test sections

Each speed was hold until reaching steady state

temperatures

• Hot start-up simulation up to normal speed 0 ➜ 27.000 rpm

Step 1 0 ➜ 9.000 rpm

• Multiple Start/Stops, with 3 steps Step 2 9.000 ➜ 18.000 rpm

Step 3 18.000 ➜ 27.000 rpm

• Multiple Start/Stops, without steps 0 ➜ 27.000 rpm

• Dynamic test at maximum continuous speed 28.350 rpm

• Dynamic test at trip speed 29.768 rpm Table 2

Impiantistica Italiana - Luglio-Agosto 2022 99 99