Page 51 - 38

P. 51

• “perceived complexity” leading to the attitu- Some oil & gas companies are

de to start from the “blank sheet” for every already exploring different operational

project and resulting in overdesign;

approaches, exploiting cutting-

• transactional contractual relationships betwe- edge technologies or adapting their

en client and service providers limiting colla- business models, ultimately investing

boration and incentives to improve; in innovation to overcome the downturn

and set the shape of the industry for

• different “sizes” of the players along the value

chain with small players hardly able to sustain the coming years.

innovation processes;

profitable and, since the first quarter of 2012, the

• wide range and frequently changing regulato- company’s well costs have dropped 47% to about

ry requirements. $ 7.1 M. Key levers of intervention for Hess have

been: standardization, continuous process impro-

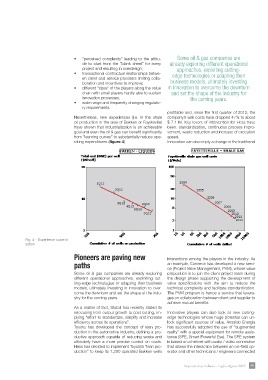

Nevertheless, new experiences (i.e. in the shale vement, waste reduction and increase of execution

oil production in the area of Bakken or Fayeteville) speed.

have shown that industrialization is an achievable Innovation can also imply a change in the traditional

goal and even the oil & gas can benefit significantly

from “learning curves” to substantially reduce ope-

rating expenditures (figure 4).

Fig. 4 - Experience curve in

action

Pioneers are paving new interactions among the players in the industry. As

paths an example, Cameron has developed a new servi-

ce (Project Valve Management, PVM), whose value

Some oil & gas companies are already exploring proposition is to join the client project team during

different operational approaches, exploiting cut- the design phase supporting the development of

ting-edge technologies or adapting their business valve specifications with the aim to reduce the

models, ultimately investing in innovation to over- technical complexity and facilitate standardization.

come the downturn and set the shape of the indu- The PVM program is hence a service that levera-

stry for the coming years. ges on collaboration between client and supplier to

achieve mutual benefits.

As a matter of fact, Statoil has recently stated its

refocusing from output growth to cost cutting, im- Innovative players can also look at new cutting-

plying “effort to standardize, simplify and increase edge technologies whose huge potential can un-

efficiency across its operations”. lock significant sources of value. Ansaldo Energia

Toyota has developed the concept of lean pro- has successfully adopted the use of “augmented

duction in the automotive industry, defining a pro- reality” with a special equipment for remote assis-

ductive approach capable of reducing waste and tance (SPE, Smart Powerful Eye). The SPE system

ultimately have a more precise control on costs. is based on a helmet with audio / video connection

Hess has decided to implement Toyota’s “lean pro- that allows the interaction between an on–field op-

duction” to keep its 1,200 operated Bakken wells erator and other technicians / engineers connected

Impiantistica Italiana - Luglio-Agosto 2015 49