Page 46 - 38

P. 46

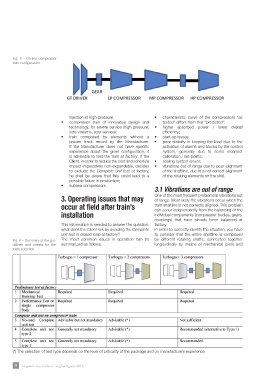

Fig. 5 - On-line compressor

train configuration

Fig. 6 – Summary of the gui- injection at high-pressure. • characteristic curve of the compressors “as

delines and criteria for the • compressor train of innovative design and tested” differs from that “predicted”;

tests selection

technology, for severe service (high pressure, • higher absorbed power / lower overall

side streams, sour service); efficiency;

• train composed by elements without a

proven track record by the Manufacturer. • start-up issues;

If the Manufacturer does not have specific • poor stability in keeping the load due to the

experience about the given configuration, it

is advisable to test the train at factory. If the activation of alarms and blocks by the control

Client, in order to reduce the cost and schedule system, generally due to some incorrect

impact imperatively non-expandable, decides calibration / set-points;

to exclude the Complete unit test at factory, • sealing system issues;

he shall be aware that this could lead to a • vibrations out of range due to poor alignment

possible failure in production; of the shaftline, due to a not correct alignment

• subsea compressors. of the rotating elements on the skid.

3. Operating issues that may 3.1 Vibrations are out of range

occur at field after train’s

installation One of the most frequent problems is vibrations out

of range. Most likely the vibrations occur when the

This information is needed to answer the question: train shaftline is not correctly aligned. This problem

what does the Client risk by avoiding the Complete can occur independently from the balancing of the

unit test in closed loop at factory? individual components (compressor bodies, gears,

The most common issues in operation can be couplings) that have already been balanced at

summarized as follows: factory.

In order to correctly identify the situation, you have

to consider that the entire shaftline is composed

by different rotating shafts, connected together

longitudinally by means of mechanical joints and

(*) The selection of test type depends on the level of criticality of the package and on manufacture’s experience

44 Impiantistica Italiana - Luglio-Agosto 2015