Page 43 - 38

P. 43

It is worth to highlight that both Mechanical • exhaust gas stack;

Running Test and Performance Test are not a test • enclosure and ventilation system and fire

on the whole compressor train (string) mounted on

the baseplate, but only the individual compressors. fighting;

Therefore, these tests should not be regarded as • oil coolers.

a simulation of the compressor train in operation.

for the electric motor:

1.3 Complete unit test • MCC (Motor Control Center);

• UCP (Unit Control Panel);

The difference with the Mechanical Running Test is • VSD (Variable Speed Driver).

that the complete compressor train (string) driver

+ compressors + gearbox + coupling mounted on for the compressor:

its own metallic baseplate is tested and not the • anti-surge system.

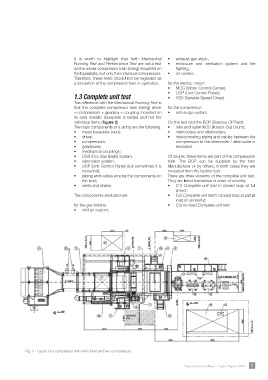

individual items (figure 2).

The main components of a string are the following: On the test bed the BOP (Balance Of Plant):

• metal baseplate (skid); • inlet and outlet KOD (Knock-Out Drum);

• driver; • intercoolers and aftercoolers;

• compressors; • interconneting piping and cables between the

• gearboxes;

• mechanical couplings; compressors to the intercooler / aftercooler is

• DGS (Dry Gas Seals) system; excluded.

• lubrication system;

• UCP (Unit Control Panel) (but sometimes it is Of course, these items are part of the compression

train. The BOP can be supplied by the train

excluded); Manufacturer or by others; in both cases they are

• piping and cables among the components on excluded from the factory test.

There are three versions of the complete unit test.

the skid; They are listed herebelow in order of severity:

• vents and drains. • C1) Complete unit test in closed loop at full

The components excluded are: power;

• C2) Complete unit test in closed loop at partial

for the gas turbine:

• inlet air system; load (in similarity);

• C3) no-load Complete unit test.

Fig. 2 - Layout of a compressor train with driver and two compressors

Impiantistica Italiana - Luglio-Agosto 2015 41