Page 45 - 38

P. 45

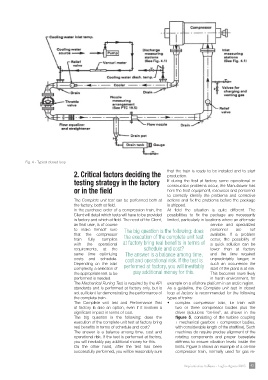

Fig. 4 - Typical closed loop

2. Critical factors deciding the that the train is ready to be installed and to start

testing strategy in the factory production.

or in the field

If during the test at factory some operational or

construction problems occur, the Manufaturer has

here the best equipment, resources and personnel

to correctly identify the problems and corrective

The Complete unit test can be performed both at actions and fix the problems before the package

the factory, both at field. is shipped.

In the purchase order of a compression train, the At field the situation is quite different. The

Client will detail which tests will have to be provided possibilities to fix the package are necessarily

in factory and which at field. The need of the Client, limited, particularly in locations where an after-sale

as final user, is of course service and specialized

to make himself sure The big question is the following: does personnel are not

that the compressor the execution of the complete unit test available. If a problem

train fully complies at factory bring real benefits in terms of occur, the possibility of

with the operational a quick solution can be

requirements, at the schedule and cost? lower than at factory

same time optimizing The answer is a balance among time, and the time required

costs and schedule. cost and operational risk. If the test is unpredictably longer; in

Depending on the train performed at factory, you will inevitably such an occurrence the

complexity, a selection of start of the plant is at risk.

the appropriate test to be pay additional money for this. This becomes more likely

performed is needed. in harsh environment, for

The Mechanical Runing Test is required by the API example on a offshore platform in an arctic region.

standards and is performed at factory only, but is As a guideline, the Complete unit test in closed

not sufficient for demonstrating the performance of loop at factory is recommended for the following

the complete train. types of trains:

The Complete unit test and Performance Test • complex compressor train, i.e train with

at factory is also an option, even if it involves a two or three compressor bodies plus the

significant impact in terms of cost. driver (solutions “on-line”, as shown in the

The big question is the following: does the figure 5, consisting of the turbine coupling

execution of the complete unit test at factory bring + mechanical gearbox + compressor bodies,

real benefits in terms of schedule and cost? with considerable length of the shaftline). Such

The answer is a balance among time, cost and machines do require precise alignment of the

operational risk. If the test is performed at factory, rotating components and proper baseplate

you will inevitably pay additional money for this. stiffness to ensure vibration levels inside the

On the other hand, after the test has been limits. Figure 5 shows an example of a on-line

successfully performed, you will be reasonably sure compressor train, normally used for gas re-

Impiantistica Italiana - Luglio-Agosto 2015 43