Page 45 - 63

P. 45

being condensed in the re-

fl ux condenser.

The purity of the remaining

water satisfi es require-

ments for usage as boiler

feed water or cooling water

make-up, which means that

Stamicarbon urea plants

do not produce any waste-

water stream. In addition

the water is reused in the

granulation plant, or can

be used for the production

of DEF, depending on the

plant confi guration.

Conclusion

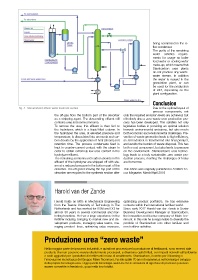

Fig. 4 - Stamicarbon’s Waste water treatment section Due to the optimal layout of

process components, not

the off-gas from the bottom part of the desorber only the required emission levels are achieved, but

as a stripping agent. The descending effl uent still effectively also a zero waste urea production pro-

contains urea and some ammonia. cess has been developed. This satisfi es not only

To remove the urea, this effl uent is then fed to legislative bodies in providing an optimal solution

the hydrolyser, which is a liquid-fi lled column. In towards environmental emissions, but also meets

the hydrolyser the urea, at elevated pressure and both economic and environmental challenges. Pre-

temperature, is dissociated into ammonia and car- vention of waste generation leads to high effi ciency,

bon dioxide by the application of heat (steam) and as all feedstock is transformed into fi nal product,

retention time. The process condensate feed is and avoids the burden of waste disposal. This has

kept in counter-current contact with the steam in both a cost component, but also leads to pressure

order to obtain extremely low urea content in the on the environment. Stamicarbon’s urea techno-

hydrolyzer effl uent. logy leads to a truly sustainable, zero waste pro-

The remaining ammonia and carbon dioxide in the duction process, meeting the challenges of today

effl uent of the hydrolyzer are stripped off with ste- and tomorrow.

am at a reduced pressure in the bottom part of the

desorber. The off-gases leaving the top part of the This article was originally published in Fertilizer Fo-

desorber are recycled to the synthesis section after cus Magazine, March/April 2018

Harold van der Zande

Harold holds an MSc in Mechanical Engineering optimizing product portfolio’s. He has extensive

from the Twente University of Technology in The contacts within the international fertilizer world.

Netherlands and has worked for DSM and OCI for Since early 2017 Harold van der Zande is Senior

almost 30 years in several commercial and mar- Business Development Manager at Stamicarbon,

keting functions. He has a large experience in the the innovation and license company of Maire Tec-

fertilizer industry, bringing to market new and de- nimont. In this role he is responsible to diversify the

velopment products, managing sales teams, ma- portfolio of Stamicarbon into other fertilizer and

naging product lines, optimizing sales revenues, non-fertilizer activities.

Produzione urea “zero waste”

Nella maggior parte dei processi industriali, e quindi nei processi per la produzione di fertilizzanti, sono emessi side

products che non possono essere ulteriormente processati, e diventano quindi rifi uti, con impatti notevoli sull’ambiente

e costi aggiuntivi per i produttori di fertilizzanti in fase di smaltimento. Stamicarbon, il centro per il licensing e

l’innovazione tecnologica del Gruppo Maire Tecnimont, ha alle spalle 70 anni di esperienza nel licensing e sviluppo

della propria tecnologia urea. Oggi questa tecnologia assicura che le emissioni di ogni fase di processo possano

essere convertite in feedstock, quasi nella loro totalità.

Impiantistica Italiana - Maggio-Giugno 2018 43